Introduction to PVC Conduit Pipe Making Machine

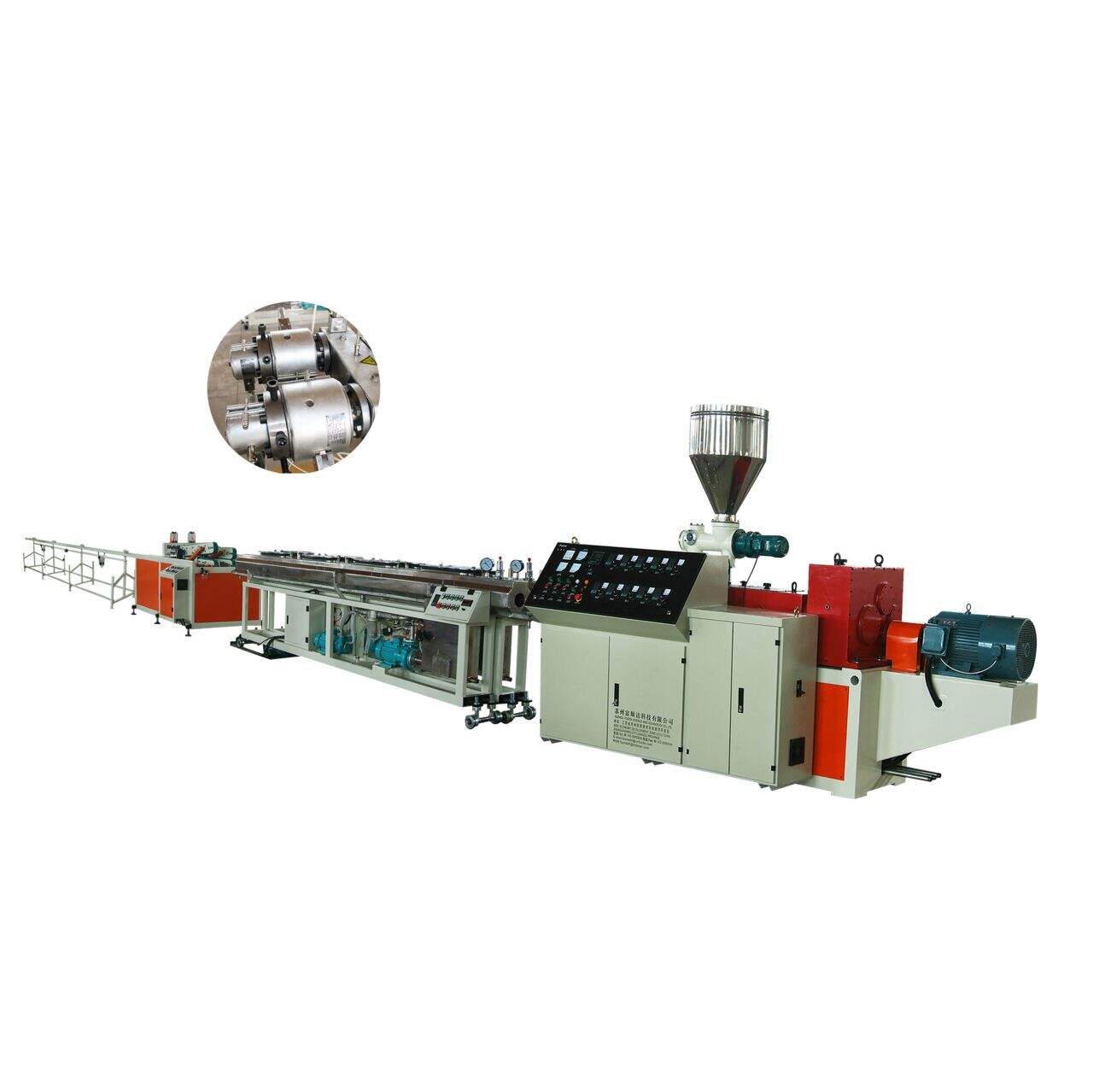

If you have ever before viewed the structure listed below building, you might have discovered long, white Pipes operating throughout the roofs and wall surfaces, just like the Fosita's product called pp pelletizing machine. These Pipes are called PVC Conduit, and they are place to protector electric electrical circuitry. PVC Conduit Pipe Making Machines are utilized to create these Pipes rapidly and easily. These Machines are essential for the building market and are utilized in numerous frameworks every day.

The PVC Conduit Pipe Making Machine has a couple of advantages over antique techniques of Pipe manufacturing, the same as plastic profile extrusion equipment by Fosita. First of all, it is quicker and much a lot extra effective compared to handbook manufacturing. Along with a PVC Conduit Pipe Making Machine, Pipes is created for a big range, conserving opportunity and power. Second of all, it produces uniform Pipes of constant quality. This assists to guarantee that all Pipes are of the similar dimension and type, which is essential for electrical circuitry. Lastly, PVC Conduit Pipe Making Machines produce Pipes which are resilient and enduring. They are immune to rust, chemical substances, and survive, Making all of them a dependable choice for safeguarding electric electrical circuitry.

PVC Conduit Pipe Making Machines are continuously being enhanced, along with Fosita's product plastic pipe production machine. Development in innovation imply that newer Machines are much a lot extra effective and develop also better Pipes. One innovation is the use of computer system setups. This allows drivers to control setups and screen the manufacturing procedure in real-time. Another innovation is the use of multi-layer extrusion innovation. This allows Pipes end up being created along with extra qualities, such because fire retardancy or even UV resistance.

Whenever running a PVC Conduit Pipe Making Machine, safety is continuously a concern, just like the machine for pvc pipe manufacturing developed by Fosita. Drivers require to use safety equipment, like handwear covers and safety glasses, to avoid trauma. They require additionally educate on how to use the Machine correctly. In regards to use, the Machine is simple to run. Drivers tons raw material right in to the Machine and after that screen the manufacturing procedure to make sure every point runs efficiently.

Fosita has high precision equipment and a knowledgeable operator guarantee high quality products. Our experts are on hand answer questions and provide prompt service. Our company accredited through ISO9001,CE,SGS and pvc conduit pipe making machine. Besides, has 6 patents that are protected by independent intellectual property rights.

Fosita has a factory of 2,000 square meters located uk Advanced Industrial Manufacturing Park. Fosita has a broad range of plastic machinery, comprising over 50 models. The machines meet the needs of customers regarding fill. Our machines are shipped over 80 countries around the globe including Middle-East Asia, Africa and South America. We've been abroad attend the annual international plastic shows.

Fosita offers a wide range of plastic machinery production lines and designs that you can choose from.Our primary products are plastic pipe production lines, plastic profiles production lines, plastic recycling machines, pelletizing machines for plastic and auxiliary machines. Fosita pvc conduit pipe making machine manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.

We provide machine pvc conduit pipe making machine service before delivery. Fosita was able reliably forwarders ensure that machine will be delivered on time. We provide complete plastic machine solution within 24 hours. Whether choosing a current item from our catalog or looking for engineering assistance for your application contact our customer service team about your requirements for sourcing.