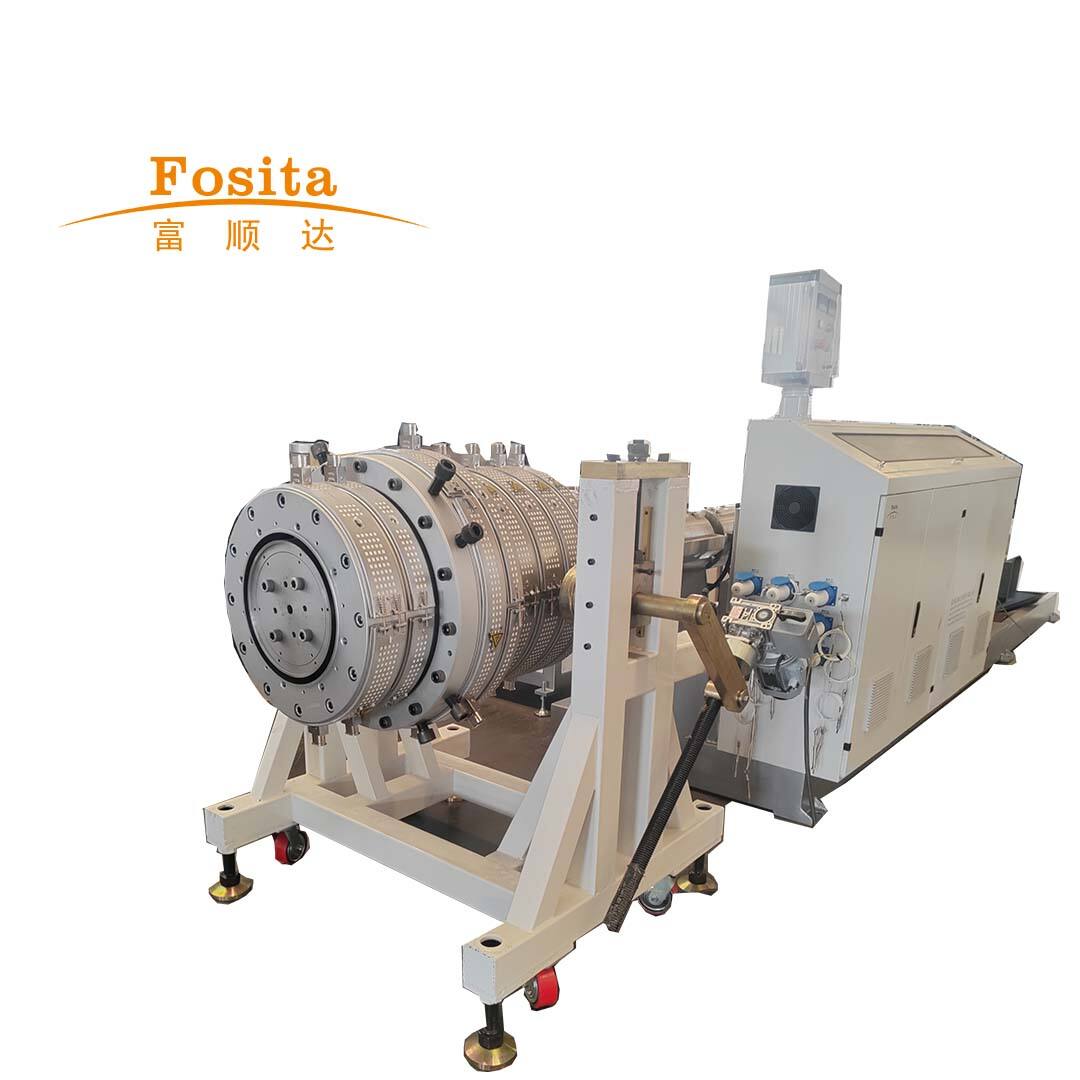

Will you be curious about how plastic pipes are manufactured? Plastic pipe production machines are responsible for manufacturing plastic pipes. They are efficient and effective, providing most benefits, innovations, safety features, and countless applications. We shall explore all the aspects of Fosita plastic pipe production machine.

Plastic pipe production machines have several advantages that make sure they are popular among manufacturers. The first is their ability to produce pipes of different diameters, lengths, and thicknesses. This versatility allows manufacturers to customize their products according to their needs.

Another advantage is the speed of production. Fosita corrugated plastic pipe machine is incredibly fast, meaning manufacturers can produce many pipes in a short amount of supply. This speed helps companies meet their product demand while increasing their profits.

Plastic pipe production machines have undergone significant innovations the ages. One of several major inventions is the feed automatic system. Using this system, manufacturers can continuously feed raw materials into the machine, saving effort and time.

Another innovation may be the control system, makes it possible for operators to obtain a grip on the entire production process and work out adjustments as required. Fosita plastic pipe extrusion line feature ensures that the machine operates at optimal efficiency, minimizing waste and reducing costs.

Using a plastic pipe production machine is fairly safer, so long as manufacturers follow safety procedures. Most machines have safety features such as crisis stop buttons, guards, and warning indications. These features reduce the chance of accidents within the workplace.

Manufacturers should also confirm that their employees receive proper training before operating the machines. This training shall include safety protocols, how exactly to use the Fosita plastic pipe making machine, and troubleshooting typical problems.

Plastic pipe production machines are acclimatized to make many types of pipes, including water pipes, gas pipes, and sewage pipes. These pipes are positioned in a variety of applications, such as irrigation, plumbing, and waste disposal. Fosita plastic tube manufacturing machine is common in residential, commercial, and industrial settings.

Fosita a manufacturer of high precision equipment and experienced operator for highest quality guarantee on products. Our engineers are available answer your questions and offer a professional service. Our company accredited through ISO9001,CE,SGS and plastic pipe production machine Besides, has 6 patents that are protected by independent intellectual property rights.

We provide machine plastic pipe production machine service before delivery. Fosita utilized a reliable forwarder make sure machine was delivered on time.

Fosita provides a variety of plastic production machinery.Our main products are manufacturing lines for plastic pipes, plastic profile production lines as well as plastic recycling machines pelletizing and plastic additional machines. Fosita plastic pipe production machine manufacturing, processing assembling of plastic extruder technology with a professional engineer and sales team.

Fosita has a factory of 2,000 square meters located new zealand Advanced Industrial Manufacturing Park. Fosita provides a complete line of plastic machinery and supply chain, which includes more than 50 models that satisfy the requirements of customers with regard the fill terms. Our machines are sold over 80 countries around the world, including Middle-east Asia, Africa and South America. We've traveled abroad participate the annual international plastic shows.

Making usage of a plastic pipe production machine are relatively uncomplicated. First, operators feed the raw materials the machine, usually a variety of resin pellets and colorants. The automatic feed then feeds the materials into the heating chamber of Fosita plastic pipe extrusion machine, where it melts and becomes a molten plastic.

The molten plastic will be pressed through a die, which shapes the materials into the desired pipe shape. The shaped tube calibrated to regulate its diameter and thickness before it cools and is cut to the desired length.

Like any other machine plastic pipe production machines regular maintenance to perform efficiently. Manufacturers should follow the manufacturer's maintenance guidelines to keep the Fosita plastic pipe manufacturing machine in close condition.

Qualified technicians should regularly inspect the machine and work out essential adjustments repairs. This helps to ensure that the machine operates at optimal efficiency, reducing downtime and upkeep costs.

Producing high-quality plastic pipes is important for manufacturers. To quickly attain this, manufacturers of Fosita plastic pipe extruder must use high-quality raw materials ensure that the production process is consistent. This persistence ensures that every pipe produced meets the specifications that's needed is reducing the risk of defective products.