Plastic Profile Extrusion Equipment: The Best Way to Create Plastic Items

Either you're the scholar or a grown-up, you've most likely come into contact with Plastic merchandise in your lifestyle. From toys to packaging, plastic is ubiquitous in modern society as it's durable and can be simply produced in various shapes and sizes. Although do you discover how plastic merchandise are made? One associated with most common methods is Plastic Profile Extrusion, that involves melting plastic pellets and shaping them into long constant components. This process requires equipment specifically made for Plastic Profile Extrusion, that has numerous advantages, innovative properties, and is safe to use. We'll explore all of these aspects of Fosita plastic profile extrusion equipment, as well as how to use it, the quality of its service, and its most applications.

First and foremost, Plastic Profile Extrusion Equipment is extremely versatile. It may be employed to build a wide range of Plastic Profiles, such as screen frames, door handles, and significantly more. Additionally, Plastic Profile Extrusion Equipment could produce goods in large amounts at a somewhat low cost. Which means that manufacturers can produce items at a faster rate and at the cheaper cost point than other manufacturing means. Moreover, Fosita profile extrusion machine could create items with consistent quality, it is key for organizations which require to meet up strict specs or laws.

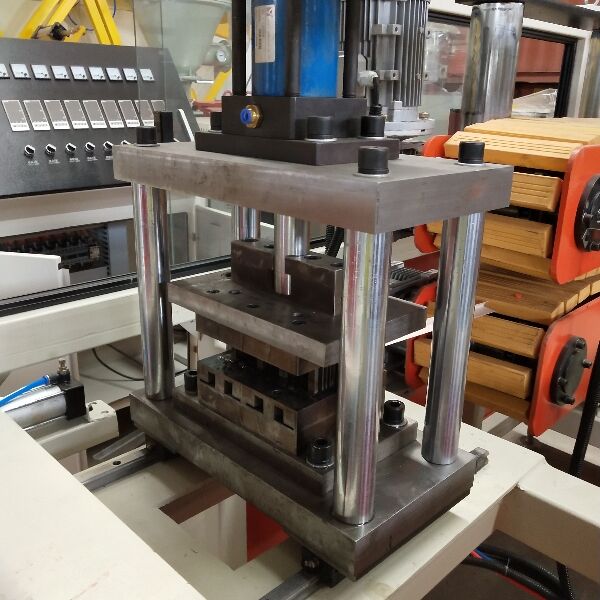

Plastic Profile Extrusion Equipment has undergone numerous changes and improvements over time. For one, newer brands have most advanced level controls and monitoring systems which assure exact temperature and pressure level for optimal product quality. Additionally, Fosita pvc profile extrusion machine is designed to build finished products best off the production line, which grows effectiveness and reduces overall production time. Lastly, many modern machines use eco-friendly technology that decreases spend and air pollution, making them the more responsible solution for companies which worry in regards to the environment.

Safety is constantly the main concern in any manufacturing setting, and Plastic Profile Extrusion Equipment is no exception. There are standard safety procedures that must definitely be adopted whenever running this Fosita extrusion pipe machine, such because wearing appropriate protective gear like goggles and gloves. Additionally, employees must be properly trained to handle the equipment and realize the dangers included. It's also crucial to regularly inspect the Equipment for wear and tear and to displace any damaged parts immediately.

Using Plastic Profile Extrusion Equipment isn't harder, however it does need some knowledge and training. When the Fosita plastic pipe extrusion machine is ready up, workers need to feed the Plastic pellets into the hopper, which melts them down and pushes them through the extrusion die to build the desired form. The process calls for proper heat and pressure settings, too as careful monitoring and adjustment to make certain constant quality. Following the products have cooled, they are able to feel cut and finished because recommended.

Fosita has high precision equipment and a knowledgeable operator guarantee high quality products. Our experts are on hand answer questions and provide prompt service. Our company accredited through ISO9001,CE,SGS and plastic profile extrusion equipment. Besides, has 6 patents that are protected by independent intellectual property rights.

Fosita has a factory of 2,000 square meters located paraguay Advanced Industrial Manufacturing Park. Fosita provides a complete line of plastic machinery and supply chain, which includes more than 50 models that satisfy the requirements of customers with regard the fill terms. Our machines are sold over 80 countries around the world, including Middle-east Asia, Africa and South America. We've traveled abroad participate the annual international plastic shows.

Fosita offers a wide range of plastic production machines.Our primary products include plastic pipe production lines, plastic profile production lines and plastic recycling equipment, pelletizing and plastic auxiliary machines. Fosita plastic profile extrusion equipment the manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.

We provide machine plastic profile extrusion equipment ervice before delivery. Fosita has a reliable forwarder ensure that machine delivered on time. We offe full plastic machine solution in 24 hours. Whether choosing a product from our catalog or seeking support from our engineers for your project, you can talk our customer support center regarding your requirements for sourcing.