Advantages of Profile Extrusion Machine

Profile Extrusion Machines have numerous advantages, similar to the Fosita's product like cost of plastic recycling machine. They could make long items of plastic with a consistent shape. This makes them well suited for making things such as pipes, tubing, and other long, thin plastic things. They have been extremely efficient, this means they could produce a complete lot of product in an in amount short supply of. Furthermore, the materials used for Profile Extrusion Machines are often very durable and resistant to wear and tear.

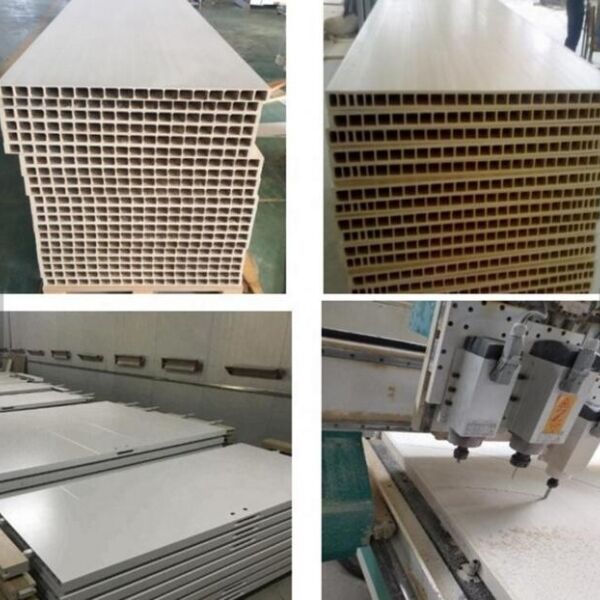

Profile Extrusion Machines have already been available for quite some time, but completely innovations new constantly being developed, along with the corrugated flexible pipe machine by Fosita. One current innovation the use of computer-controlled systems to monitor and get a handle on the Extrusion procedure. This permits for tighter control over the method and implies that the item being produced is of consistent quality. Another innovation will be the use of differing types of plastics and additives that may be employed to generate different properties the completed product.

Safety is an important consideration utilizing a Profile Extrusion Machine, as well as the Fosita's plastic pipe production machine. There are several moving parts involved in the method, and proper safety needs to be followed in order to avoid accidents. Operators should always wear appropriate safety, such as gloves and safety spectacles, and learn within the appropriate use of the Machine. The Machine itself also needs to be made with safety at heart, with features such as crisis stop buttons and safety guards.

Making use of a Profile Extrusion Machine is simply an easy operation, same with the plastic recycling dana machine supplied by Fosita. The very action first to prepare the plastic-type ideal material for the Extrusion. This might involve melting the plastic, mixing it along with other materials, or adding ingredients generate properties being specific. The ready material then fed in to the extruder, which forces it through a die to create the required form. The completed item then cooled and cut to your desired length.

When buying a Profile Extrusion Machine it is important to select a maker that gives good service and quality, also the Fosita's product such as wpc board extrusion line. This includes specific things like responsive customer support, timely maintenance and repairs, and reliable parts availability. Additionally, the Machine itself should be built to last and be easy to maintain. Try to find a maker having a good reputation the industry and a reputation creating high-quality Machines.

Fosita has a factory of 2,000 square meters located rwanda Advanced Industrial Manufacturing Park. Fosita provides a complete line of plastic machinery and supply chain, which includes more than 50 models that satisfy the requirements of customers with regard the fill terms. Our machines are sold over 80 countries around the world, including Middle-east Asia, Africa and South America. We've traveled abroad participate the annual international plastic shows.

Fosita boasts high-quality equipment as well as an experienced and skilled operator offer high quality product guarantee. Our experts are on hand answer questions and provide prompt service. Our company accredited through ISO9001,CE,SGS and profile extrusion machine. Besides, has 6 patents that are protected by independent intellectual property rights.

Fosita offers a wide range of plastic production machinery.Our main products are manufacturing lines for plastic pipes, plastic profiles production lines and recycling machines for plastic, pelletizing and plastic auxiliary machines. Fosita specialized the profile extrusion machine, processing, assembling of plastic extruder technology with professional engineer and sales team.

We provide machine profile extrusion machine service before delivery. Fosita employed a dependable forwarder make sure machine was delivered on time.