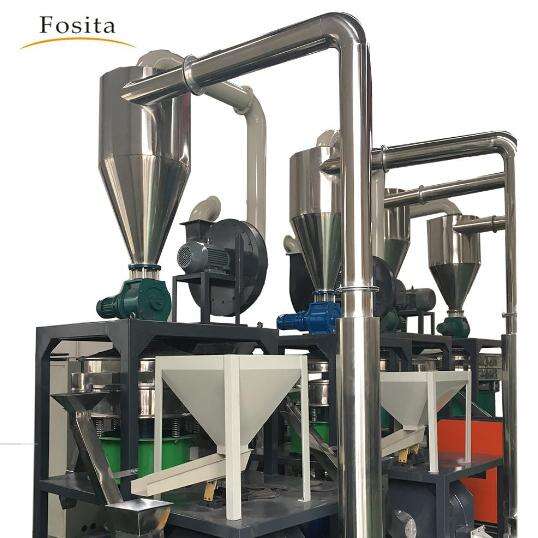

Fosita PC400 300-450kg/h Plastic Bottle Crusher Recycling Crushing Machine

| Place of Origin: | China |

| Brand Name: | FOSITA |

| Model Number: | PC400 |

| Certification: | CEISO9001 |

| Minimum Order Quantity: | 1 set |

| Price: | USD2000 |

| Packaging Details: | Plastic films or wooden packaged |

| Delivery Time: | 15 Days |

| Payment Terms: | T/T L/C |

| Supply Ability: | 50 sets per month |

- Overview

- Parameter

- Features

- Inquiry

- Related Products

Fosita claw type plastic crusher are especially suitable for larger and harder subjects like injection lump plastics, etc. Blade sets made by once cutting from steel plate, adopted with patent front-positioning blades design enlarging cutting angle and increasing cutting efficiency. Hence the output granules are even and with less powder or dust occurred. Models are divided into claw and flat types with wide applications.

01 High-strength Blades

1.The main spindle blade holder is made of 45# steel and undergoes quenching and tempering treatment.

2.The blade material is CR12MOV, with a hardness of 57-59 degrees.

3.The blades are installed using internal hexagon socket screws, which prevents the screws from wearing out due to prolonged use.

02 Soundproofing Design

The feeding hopper features a double-layer soundproof design on all four sides. The inner layer is made of stainless steel, and it is filled with soundproofing material in the middle. This design provides excellent noise reduction and ensures a quiet operation

03 Electrical Components

The equipment is equipped with globally renowned Siemens electrical components, ensuring the stability of its performance and providing a high level of safety and reliability.

Specifications

| Model | Fixed Blade Qty | Rotary Blades Qty | Motor Power(KW) | Capacity(KG/H) | Crushing Caliber(mm) |

| PC230 | 2 | 6 | 4 | 150-200 | 200*230 |

| PC300 | 2 | 9 | 5.5 | 200-250 | 220*308 |

| PC400 | 2 | 12 | 7.5 | 300-450 | 245*408 |

| PC500 | 2 | 15 | 11 | 400-720 | 280*508 |

| PC600 | 4 | 18 | 15 | 450-900 | 340*608 |

Applications:

Plastic bottle crusher machine is widely used in the rubber and plastic industry, including bottle blowing machines and blow molding machines. It is capable of directly crushing various shapes of hollow blow-molded barrels, including square and round PC/PET hollow blow-molded barrels, as well as mineral water bottles, gallon drums, paint buckets, chemical barrels, and more of various sizes. Additionally, this bottle crusher exhibits outstanding processing capability, with the ability to directly crush hollow barrels of up to 200 liters in siz

Quick Detail

1,plastic crushing machine

2,To crushing plastic bottles or soft pipes

3,150-800kg/h capacity

4.Automatic with low noise

Competitive Advantage

1. Easy to operate, low electricity consumption & durable and Low nosie.

2. Uses Japan's high quality steel material especially for making cutter of the crushers.

3. The blades can be grinded for many times and can be used repeatedly.

4. Easy to clean and maintain; The hopper, crusher room, blades and screen can be removed and mounted easily.

5. Brand Motor and SCHNEIDER ELECTRIC with Over-loading protection

6. To crush all kinds of soft and hard plastic. High reliability, High efficiency and other plastic recycling industry

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH