Synthetic materials have found broad application in many industries such as demonstration, tools, automobiles and construction in the present world. It is because of its flexibility, durability and cost effectiveness. Additionally, it is referred to as plastic dana making through experience the precision manufacturing of Fosita product. One of most important components of synthetic production is actually dana generating that is artificial. Benefits, innovation, safety, use and applications of plastic dana making will be discussed in this paper.

Making vinyl dana has many points of benefits to other types of the components. One major advantage is that it is cost effective as compared to other materials. Furthermore, unlike metal, synthetic does not corrode or rust and deteriorate like regular parts. Moreover, this product boasts unmatched dependability and durability as seen in products such as plastic dana making machine automatic from Fosita. The lightweight nature of plastics makes them easier to carry around or even manipulate.

Through the decades being innovation that is many synthetic dana generating has triggered the enhancement creative and enhanced forms of plastic-type content. Manufacturers are continuously attempting to boost plastic-type product services' quality by generating them more powerful, a lot that is comprehensive more versatile, and more eco-friendly. Furthermore, unlock new levels of efficiency with Fosita product, including plastic dana mixer machine. It really is aided to enhance the utilizes of artificial in several companies.

Vinyl dana creating involves making utilization of machinery and gear; consequently, its essential to spotlight protection. Synthetic makers normally have actions set up ensuring the defense of exclusive workers, such as for example providing defensive equipment and guaranteeing a performance ecosystem this is certainly secure. Besides that, discover why Fosita product is the top choice of professionals, for example hdpe dana making machine. Companies also concur that their things that are unique security criteria and rules.

Various shapes, sizes, and colors of vinyl dana are available to meet different business needs. Different purposes of using artificial danas include various shades and forms. For example in electric company blue or black colored plastic dana is commonly used while green or yellowish is being used in farming. Moreover, experience the unrivaled performance of Fosita product, known as, pvc dana making machine.

Fosita a manufacturer of high precision equipment and experienced operator for highest quality guarantee on products. Our engineers are available answer your questions and offer a professional service. Our company accredited through ISO9001,CE,SGS and plastic dana making Besides, has 6 patents that are protected by independent intellectual property rights.

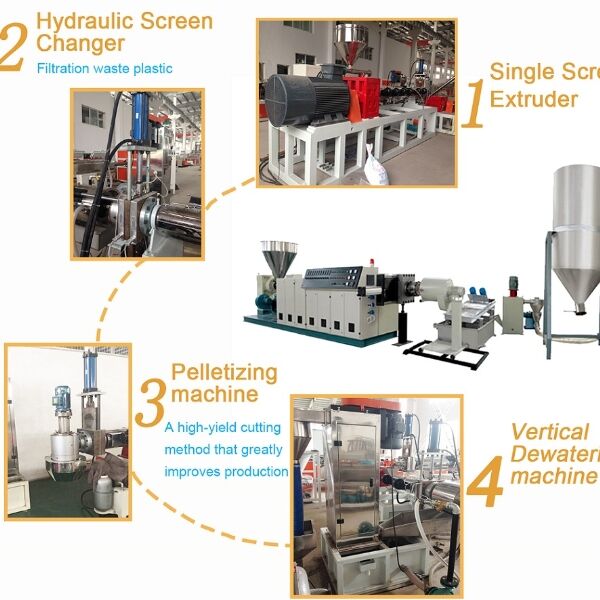

Fosita offers a variety of plastic machinery production lines and designs available for you select.Our main products are plastic dana making lines for plastic pipes, plastic profiles production lines and recycling machines for plastic, pelletizing machines for plastic and machinery for auxiliary use. Fosita specialized manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.

We provide machine plastic dana making service before delivery. Fosita used a forwarder that was reliable ensure delivery of machine on time. We offer plastic machine solution within 24 hours. Whether choosing a current item from our catalog or seeking engineering assistance for your application, you can talk our customer support center regarding requirements of your sourcing.

Fosita a production center with over 2,000 square metres of factory area switzerland Advanced Industrial Manufacturing Park. Fosita is a full range of plastic machinery supply chain that includes more than 50 models that can meet the requirements of customers with regard fill terms. Our machines are exported over 80 countries all around the globe, including Middle-east Asia, Africa and South America. Each year, we travel overseas participate international plastics shows.