100-800kg/h Plastic PVC Hot-cutting Pelletizing Line

| Place of Origin: | China |

| Brand Name: | Fosita |

| Model Number: | FST-Pelletizing |

| Certification: | CE ISO |

| Minimum Order Quantity: | 1 set |

| Price: | USD25,000 |

| Packaging Details: | Film or wooden package |

| Delivery Time: | 30 days |

| Payment Terms: | T/T L/C |

| Supply Ability: | 5 sets per month |

- Overview

- Parameter

- Features

- Inquiry

- Related Products

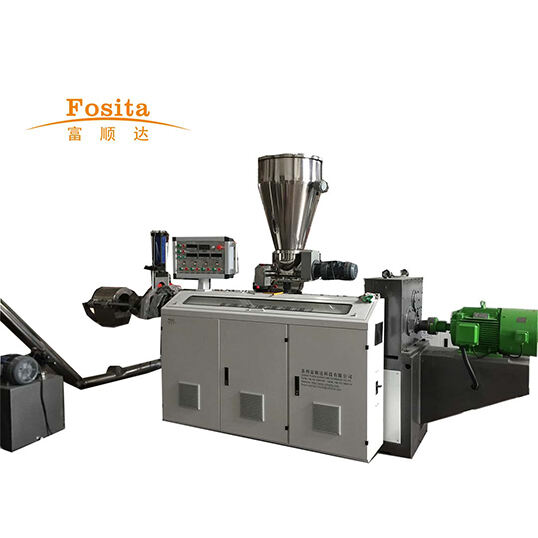

PVC pelletizing machine

This pelletizing line is mainly used for pelletizing PVC powder materials , which adopts hot-cutting method. The capacity is from 100kg/h to 800kg/h. The precision of pelletizing is perfect, installation and operation are easy and convenient.

Fosita PVC hot cutting pelletizing line is composed by a conical twin-screw extruder and the correspondingly pelletizing downstream equipment, it is suitable for the pelletizing of PVC raw materials with wood powder or other additives.The pellets produced by this machine is evenly, solid, elegance.

The pelletizing downstream equipment is the die face cutter, air transferring unit, vibration separating and cooling unit. This pelletizing downstream equipment has the features of high automation and high production efficiency.

It has fine plasticizing, high productive efficiency, impact construction in the whole machine and high automatization, adopts conical twin screw installs on the extruder.

Process flow of plastic pvc pellets making production machine line Raw material+ additive → Mixing → Conveying feeding → hopper feeding → Conical twin screw extruder → Hot face cutting → Cyclone separator → Vibration sieve → Blowing system → Storage hopper → Finished product packing

Specifications

| Pipe line Model | Extruder Model | Output(kg/h) | Main Motor Power(KW) |

| FST-150 | SJSZ55/110 | 100-150 | 22 |

| FST-250 | SJSZ65/132 | 200-250 | 37 |

| FST-400 | SJSZ80/156 | 350-400 | 55 |

| FST-800 | SJSZ92/188 | 650-800 | 110 |

Applications:

With different designs of screw, this machine can be applied to granulate the recycled material of rigid PVC, soft PVC and waste PVC.

It used pneumatic conversion and strong-wind blowing. At the same time can adjust stainless steel storage container and can run at high speed for a long time while extrude stably.

PVC material mixture with other materical,such as: CaCO3, CPE, static, wax and so on. The granules/ pellets can be used to producing PVC profiles and shoes, and so on.

Quick Detail

1.plastic granulating machine; plastic pelletizing machine

2.To make PVC powder into PVC pellets or granules

3.100-800kg/h

Competitive Advantage

1.Advanced equipment, precise pelletizing and high producing capacity of plastic pelletizing machine

2, Conical double-screw extruder, very suitable to process PVC powder with high capacity

3, Pelletizing style: Hot-cutting on mould face, even cutting ensures good shape.

4, Auxiliary machine: Pellets cooling & classifying

Tag

Plastic pelletizing machine with noodle cutting, plastic cold-cutting granulating machine, cold-bracing plastic pelletizing line,Double stage plastic pelletizing line.

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH