150-500kg/h Plastic PP/PE Film Recycling and Granulating Water-ring Pelletizing Machine Line

| Place of Origin: | China |

| Brand Name: | Fosita |

| Model Number: | FST-Pelletizing |

| Certification: | CE ISO |

| Minimum Order Quantity: | 1 set |

| Price: | USD28,500 |

| Packaging Details: | Film or wooden package |

| Delivery Time: | 30 days |

| Payment Terms: | T/T L/C |

| Supply Ability: | 5 sets per month |

- Overview

- Parameter

- Features

- Inquiry

- Related Products

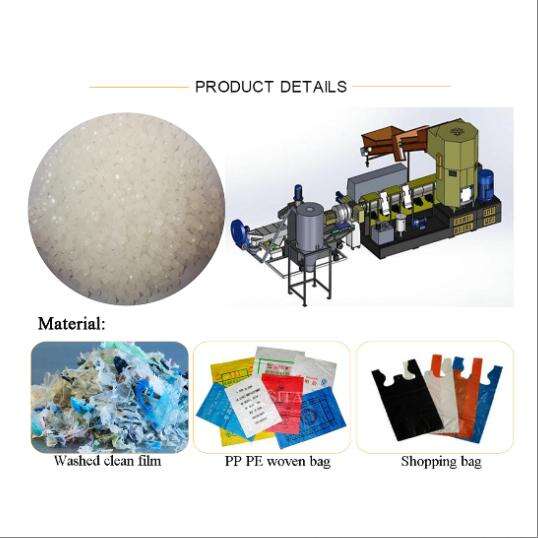

Fosita PP PE recycling and pelletizing machine gathers so many functions of crushing, compacting, plasticization and pelletizing to a whole system. We have adopted advanced European technology recently that makes sure quality and long usage time.

This plastic pelletizing machine can used for granulating many kind of raw material such as plastics films, woven bags and foaming materials re-pelletizing.

Process flow of plastic granulating machine : Convey feeder→Compactor→Extruding machine→ High speed screen exchanger→ water-ring pelletizing machine (or strand cutting)→Spin Dryer → Storage silo

There are many advantages:

1. Suitalbe for plastic film PP ,PE ,HDPE,LDPE,LLDPE and so on.

2. Equipped with the vertical and horizontal force-feeding device to ensure high output.

3. Vent design on the barrel to evaporate the volatiles form the recyle material.

4. Hydraulic screen change unit and pressure gauge for easy operation and safety.

5. Water chamber with die face cutter simplifes the process.

6. The vertical centrifuge separates and dry the pellets faster.

7. High-efficient force-feeder ensures high capacity feeding, low energy consumption.

8. Plastic pelletizer style: water-ring cutting with extrusion mould, even cutting ensures good shape.

Specifications

| Pipe line Model | Extruder Model | Output(kg/h) | Line Length(m) |

| FST-150 | SJ100 | 150-180 | 10 |

| FST-300 | SJ120 | 200-300 | 15 |

| FST-500 | SJ150 | 400-500 | 20 |

Applications:

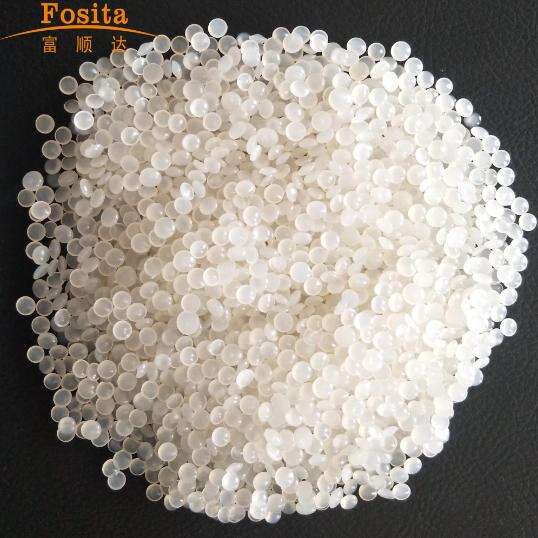

Final productions are in the form of pellets/granules, which can directly put into the production line for blowing moulding machine, plastics injection machine, etc.

Quick Detail

1.plastic granulating machine; plastic pelletizing machine

2.To recycling plastic films and make into pellets or granules

3.150-500kg/h

Competitive Advantage

1.Equipped with the vertical and horizontal force-feeding device to ensure high output.

2.Vent design on the barrel to evaporate the volatiles form the recyle material.

3.Hydraulic screen change unit and pressure gauge for easy operation and safety.

4.Water chamber with die face cutter simplifes the process.

5. The vertical centrifuge separates and dry the pellets faster.

Tag

Plastic pelletizing machine,plastic granulating machine,plastic pelletizing line

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH