Fosita SJ45 SJ65 SJ75 Plastic PE PP PVC Single Screw Extruder Machine for Pipes Profiles

| Place of Origin: | China |

| Brand Name: | FOSITA |

| Model Number: | FST-Extruder |

| Certification: | CE ISD9001 |

| Minimum Order Quantity: | 1 set |

| Price: | USD15,000 |

| Packaging Details: | Film or wooden packaged |

| Delivery Time: | 30 days |

| Payment Terms: | T/T L/C |

| Supply Ability: | 5 sets per month |

- Overview

- Parameter

- Features

- Inquiry

- Related Products

Single screw extruder consists of three parts including extrusion system, transmission system and heating and cooling system

The main role of the extrusion system is to form a uniform melting of polymer materials to form a uniform melt, and realize the transition from glass state to adhesive. In this process, a certain pressure is established, and the screw is continuously squeezed and transported to the head mold.

The Dynamic system is usually composed of electric motors, reducers, and bearings. Its role is mainly driving screws to provide the torque and torque required for the screw in the process of extrusion.

The heating and cooling system of the extruder is composed of heating device and cooling device. It is a necessary condition for the squeezing process. The heating device and cooling device must ensure the melting plasticization of the polymer materials and the temperature conditions in the molding process to reach the process.

The Plastic single screw extruder is the main machine on Plastic pipe making machine or pelletizing machine.

The screw and barrel material is 38CrMoAIA with nitriding treatment.

The model size of the extruder is according to your pipe diameter or capacity you need.

Specifications

| Model | Motor Power(KW) | Heating Power (KW) | OutPut(Kg/H) |

| SJ25/25 | 1.5 | 2 | 3 |

| SJ30/25 | 3 | 3 | 8-12 |

| SJ45/25 | 7.5 | 8 | 25-35 |

| SJ45/30 | 11 | 9 | 30-40 |

| SJ50/30 | 15 | 10 | 45-55 |

| SJ65/25 | 22-30 | 12 | 80-100 |

| SJ65/33 | 45 | 18 | 100-160 |

| SJ75/33 | 55 | 18 | 120-180 |

| SJ90/33 | 90 | 32 | 200-300 |

| SJ120/33 | 250 | 48 | 700-900 |

| SJ150/33 | 315 | 76 | 1000-1300 |

Quick Detail

1. Single screw extruder

2. To make plastic pipes, profiles and pellets

Competitive Advantage

1. High lineal extrusion speed, big capacity and low power consumption, and achieved multi-layers co-extrusion with 1-5 layers.

2. The copper bush is more wear-resisting and prevent material leakage which can guarantee a stable running of extruder.

3. Material feed via spiral groove, efficient transmission and can effectively reduce back-pressure on extruder.

4. Unique design (barrier, shearing and mixing zone) guarantees a uniformed plasticizing effect, and can reduce the pressure on the screw which guarantees a high speed and stable output capacity.

5. High torque gear box has a smart figuration, compact construction, low noise, high carrying capacity, high transmission efficiency can assure long-time trouble-free operation;

6. PCA(pipe air cooling system) of die head largely increase the extrusion speed and decrease the cooling length of extrusion line, and improve quality of inner pipe surface;

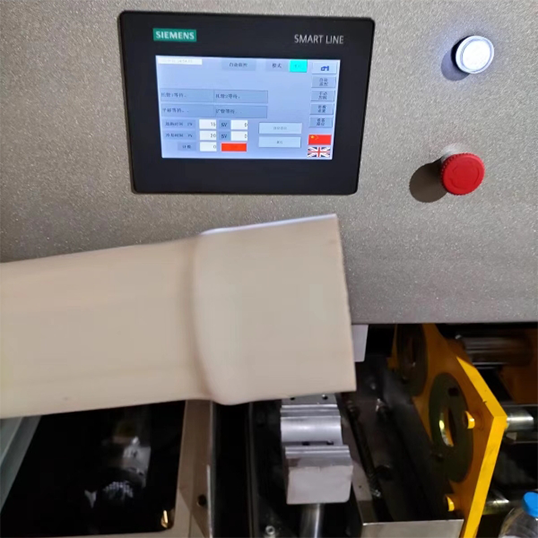

7. Intelligent PLC controlling system with human-friendly interface make the operation easily and conveniently;

8. Chip-free cutter ensuing flat and smooth cutting surface of pipe.

Tag

Single screw extruder, plastic extruder machine, single screw extruder machine,pp pe single screw extruder

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH