Fosita 16-800mm Multiple Layers Plastic PE HDPE PPR Composite Pipe Extrusion Machine Production Line

| Place of Origin: | China |

| Brand Name: | FOSITA |

| Model Number: | FST-PE Pipe |

| Certification: | CE ISD9001 |

| Minimum Order Quantity: | 1 set |

| Price: | USD45,000 |

| Packaging Details: | Film or wooden packaged |

| Delivery Time: | 30 days |

| Payment Terms: | T/T L/C |

| Supply Ability: | 5 sets per month |

- Overview

- Parameter

- Features

- Inquiry

- Related Products

1. Two sets Single Screw Extruders with one Co-extruder

High production efficiency, Steady running, lower maintenance cost.

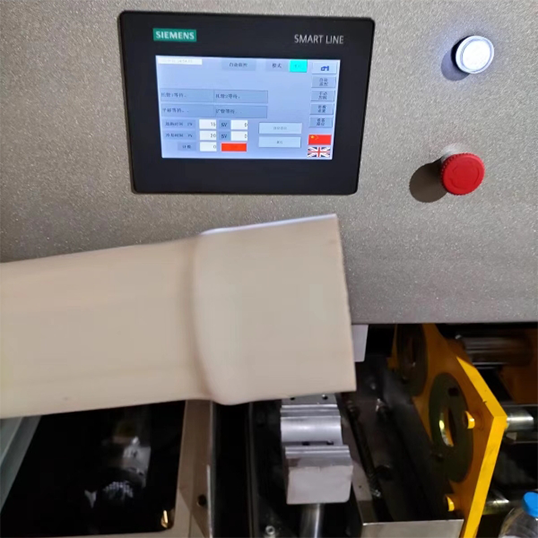

Optional PLC control system or Manual type is optional at customer's requests for machine operation.

Superior quality of high speed gear box, with advantages of high torque, high speed, low noise, hard gear tooth face, it can prolong its service life

Siemens, ABB, Schneider, RKC, Omron and so on, as Standard Electrical Part.

Optional choice: weight per meter for material control device, can make sure the weight of per meter for extruded pipe

2. CO-Extrusion die

Extrusion head with spiral structure, make sure the melt in side distributed evenly so as to achieve best plasticization.

Calibrator design with water ring which is easy to clean, to achieve better cooling and then fast forming.

3. Vacuum tank and Spray tank

Thick stainless steel as raw material for vacuum tank, it will make sure long service life.

Advanced pipe line layout design and adjustable spray angle for better cooling effect, and fast cooling.

4. Haul-off machine

For different pipe size and different speed requirement, we have developed kinds of haul-off unit accordingly.

The haul-off unit equipped with single motor drive for every claw with separate motor drive, there is the belt type haul-off unit, stable hauling.

5. Plastic Pipe Cutter

Reasonable cutting design with Universal clamp, and stable for cutting.

According to the requirement pipe length, to do automatic cutting by encoder, and the Cutted pipe smoothly.

6. Coiler/winder

Single or Double station coiler is available.

7. Stacker

Easy design for socket to collect the extruded pipe.

Specifications

| Model | Diameter(mm) | Extruder | Power(KW) | OutPut(Kg/H) |

| FST-63 | 16-63 | SJ65/33 SJ25/25 | 110 | 120-180 |

| FST-110 | 16-110 | SJ65/33 SJ25/25 | 130 | 150-200 |

| FST-160 | 50-160 | SJ75/33 SJ25/25 | 150 | 150-220 |

| FST-250 | 75-250 | SJ75/33 SJ25/25 | 280 | 280-350 |

| FST-315 | 110-315 | SJ90/33 SJ25/25 | 350 | 250-350 |

| FST-450 | 160-450 | SJ90/33 SJ25/25 | 400 | 350-450 |

| FST-630 | 315-630 | SJ120/33 SJ25/25 | 550 | 550-850 |

| FST-800 | 450-800 | SJ150/33 SJ25/25 | 750 | 800-1300 |

Quick Detail

1. Multiple layers pe hdpe pipe production line

2. To make multiple layers plastic pe/hdpe pipes

Competitive Advantage

1. This Large diameter HDPE/MDPE fuel gas/water supply pipe extrusion line is mainly used for producing large diameter HDPE/MDPE pipe. The pipe has some excellent features such as heating resistant, aging resistant, high mechanical strength, environmental stress cracks resistant, good creep resistant, etc. It is a preferred gas conduit for ductwork systems between city and its suburb, water supply in city.

2. High efficiency extruder is designed for HDPE pipe, equipped with reducer which is high speed and low noise, feeding section with cooling unit and reversing spiral groove, different pitch undulant screw which allows great output, lower melting temperature, and lower energy consumption.

Distributed spiral composite extrusion die-head ensures the melting pressure and flux even and stable, the surface of pipe smooth and glossy.

Tag

Multiple layers pe hdpe pipe machine, three layers plastic pe pipe machine, pe/hdpe pipe extrusion machine.

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH