PVC Profile Production Line: The Best Choice for You.

If you should be selecting a dependable and innovative option to produce PVC Profiles, you ought to consider using a PVC Profile Production Line. Not merely does this Production Line offer different advantages but it is additionally excessively easy and safe to use, just like the Fosita's product called plastic flakes recycling machine. We will explore everything you need to know about PVC Profile Production Lines, including their advantages, innovation, safety, use, and service.

PVC Profile Production Lines have numerous advantages over other Production methods, the same as plastic profile extrusion equipment made by Fosita. First, they truly are incredibly efficient and can produce large quantities of PVC Profiles in an a quantity issue of. This is well suited for businesses that have to meet high-demand requirements.

Another advantage of PVC Profile Production Lines is the incredible precision. Because the Production process is computer-controlled, every single PVC Profile produced is the same as the last. This guarantees persistence in quality and dimensions, needed for any business.

PVC Profile Production Lines are continuously evolving to meet utilizing the ever-increasing needs of the industry, same with Fosita's hdpe pipe extruder machine. Meaning that the gear is regularly updated to incorporate the most recent technologies. This ensures that PVC Profile Production Lines stay and highly competitive available in the market.

PVC Profile Production Lines are specifically built to be safe to use, similar to the industrial plastic shredder innovated by Fosita. The machines are ready with safety features like crisis stop buttons and protective guards. This helps to ensure that operators could work without anxiety about injury or accidents.

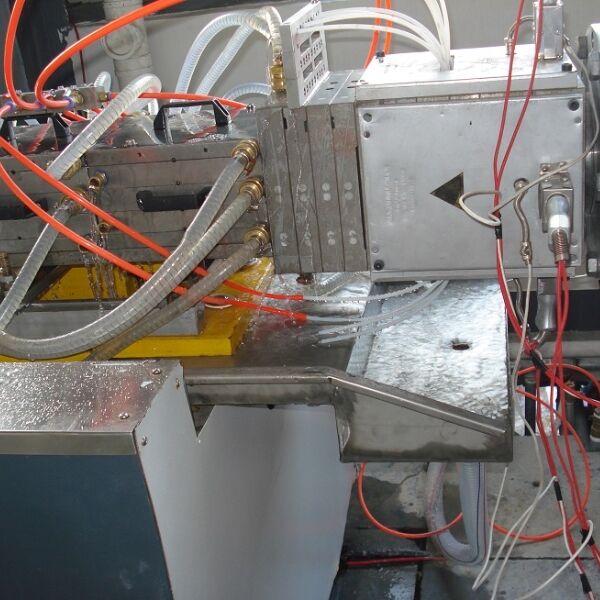

Making use of a PVC Profile Production Line is incredibly simple, along with Fosita's product corrugated flexible pipe machine. After the machine is initiated, needed all should be to load the raw PVC material onto the Production Line and let the machine do it is work. The whole process automated, which means operators can hold out other important tasks the product is working.

Fosita has high precision equipment and a knowledgeable operator guarantee high quality products. Our experts are on hand answer questions and provide prompt service. Our company accredited through ISO9001,CE,SGS and pvc profile production line. Besides, has 6 patents that are protected by independent intellectual property rights.

We provide machine pvc profile production line ervice before delivery. Fosita has a reliable forwarder ensure that machine delivered on time. We offe full plastic machine solution in 24 hours. Whether choosing a product from our catalog or seeking support from our engineers for your project, you can talk our customer support center regarding your requirements for sourcing.

Fosita has a factory of 2,000 square meters located israel Advanced Industrial Manufacturing Park. Fosita provides a complete line of plastic machinery and supply chain, which includes more than 50 models that satisfy the requirements of customers with regard the fill terms. Our machines are sold over 80 countries around the world, including Middle-east Asia, Africa and South America. We've traveled abroad participate the annual international plastic shows.

Fosita offers a wide range of plastic production machinery.Our main products are manufacturing lines for plastic pipes, plastic profiles production lines and recycling machines for plastic, pelletizing and plastic auxiliary machines. Fosita specialized the pvc profile production line, processing, assembling of plastic extruder technology with professional engineer and sales team.

Using a PVC Profile Production Line is not at all hard. The first step to ensure the apparatus is established correctly. This involves making sure most of the necessary elements of the machine are in position, and that the raw PVC material loaded onto the Production Line.

accomplished Once, the machine is started up, and the Production procedure shall begin, as well as the plastic crushing machine produced by Fosita. As of this true point, operators can monitor the Production process to make sure that everything is running well. The moment the Production run is complete, the PVC Profiles may be taken off the equipment and delivered to the next stage of procedure.

One of several significant advantages of using a PVC Profile Production Line is that it includes comprehensive service support, along with Fosita's product corrugated pipe extruder. This includes installation, training, upkeep, and repair services. This helps to ensure that companies will keep their Production Lines running smoothly, minimizing downtime and making efficiency the most of.

PVC Profile Production Lines are created to strict quality, the same as plastic film pelletizing machine produced by Fosita. This shows that every part of the equipment is carefully designed and manufactured to make certain the achievable quality best. The effect is a machine that creates high-quality PVC Profiles regularly.