Why Profile Extrusion Equipment is a Must-Have in Manufacturing

Are you currently into the manufacturing industry and searching for a real way boost your production process? Look no other further than profile extrusion equipment. This innovative machinery a game-changer for businesses of most sizes. Let's break down the advantages, safety precautions, and service options of Fosita profile extrusion equipment.

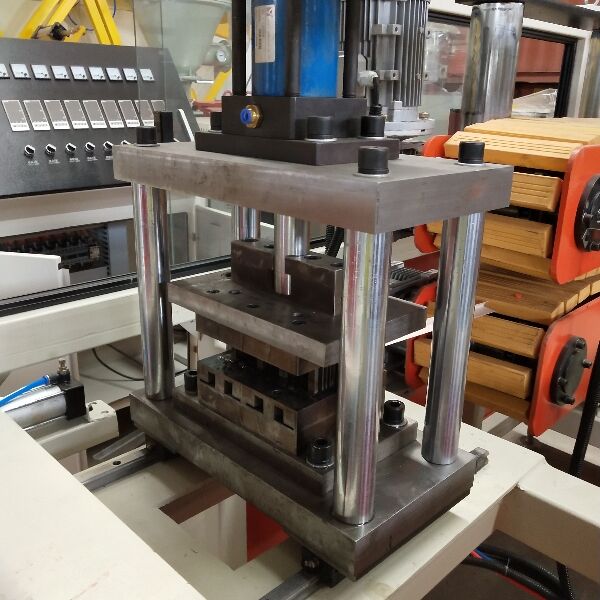

Profile extrusion equipment is the clear perfect answer companies that want the creation of constant and complex shapes. One of the biggest features of this equipment is its capacity to produce customized parts. This means that businesses can create unique shapes tailor-made for his or her specific needs.

An additional great benefit is the fact it is incredibly efficient. The Fosita pvc profile extrusion machine allows for high-speed production, maximizing output and reducing downtime.

Safety should be a high priority in any manufacturing environment. why profile extrusion equipment is made with a real amount of safety features. By way of example, the equipment typically comes with screens that will protect operators from hazardous debris or dust that could cause harm potentially.

In addition, safety protocols are implemented in to the usage of the Fosita profile plastic extrusion line. Operators are given specific instructions how to safely operate the equipment. Including wearing protective gear ensuring the equipment is precisely maintained, and after strict guidelines while using the machinery.

When investing in machinery, it is vital to consider the ongoing service quality of the equipment. With profile extrusion equipment, businesses can get top-notch consumer service and high-quality machinery.

Service alternatives for this Fosita plastic profile extrusion equipment include anything from installation to maintenance and repairs. This helps to ensure that businesses can always keep their machinery running efficiently, minimizing downtime and maximizing productivity.

With regards to quality, profile extrusion equipment is made for durability. Which means businesses can rely on their machinery to continue for years to come.

As technology will continue to advance, so does the global world of machinery. profile extrusion equipment is no exception. In reality, this sort of Fosita profile extrusion line has seen significant innovation modern times, which makes it a far more appealing investment businesses.

Perhaps one of the most notable innovations could be the incorporation of advanced software. This software enables more precise control the manufacturing process, resulting in even greater efficiency and productivity.

Fosita offers a variety of plastic machinery production lines and designs available for you select.Our main products are profile extrusion equipment lines for plastic pipes, plastic profiles production lines and recycling machines for plastic, pelletizing machines for plastic and machinery for auxiliary use. Fosita specialized manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.

Fosita a production center with over 2,000 square metres of factory area uganda Advanced Industrial Manufacturing Park. Fosita is a full range of plastic machinery supply chain that includes more than 50 models that can meet the requirements of customers with regard fill terms. Our machines are exported over 80 countries all around the globe, including Middle-east Asia, Africa and South America. Each year, we travel overseas participate international plastics shows.

Fosita boasts high-quality equipment as well as an experienced and skilled operator offer highest quality guarantee on products. Our experts are on hand answer questions and provide a thoughtful service. Our company accredited through ISO9001,CE,SGS and profile extrusion equipment. Besides, has 6 patents that are protected by independent intellectual property rights.

We provide machine profile extrusion equipment service before delivery. Fosita employed a dependable forwarder make sure machine was delivered on time.