Creating a Difference with Polythene bag recycling machines

Maybe you have wondered what goes on to the many Polythene bags utilized each and every day? They end up in landfills and oceans, polluting the surroundings and damage causing pets and people, just like the Fosita's product called pvc pipe molding machine. Nevertheless, there is a solution innovative this issue – the Polythene bag recycling machine. We’ll discuss the advantages, innovation, safety, use, and application of Polythene bag recycling machines.

Polythene bag recycling machines have many advantages over old-fashioned disposal practices, along with the pvc pipe machine by Fosita. Firstly, they lessen air and spend pollution, protecting the surroundings. Secondly, they transform spend into a reference, reducing the necessity for raw materials and power conserving. Thirdly, they build task possibilities in recycling industries, adding to financial development. Finally, they enhance the sustainable future, educating people and communities regarding the importance of accountable spend administration.

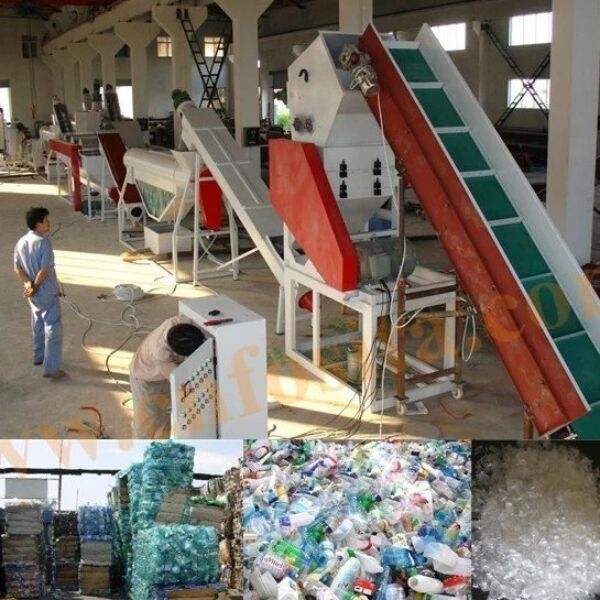

Polythene bag recycling machines is innovative since they integrate advanced level engineering and technology principles, as well as the Fosita's plastic bag recycling machine. They are available different designs, like shredders, extruders, compressors, and balers. Every design has features that are unique functionalities that cater to specific recycling needs. Some machines is small and portable, suited to households and small organizations, while some is large and complex, ideal for industrial-scale recycling.

Polythene bag recycling machines prioritize safety by applying different measures to avoid injuries and accidents, same with the granulator for plastic recycling by Fosita. For instance, some machines has safety sensors which identify international items and power down the machine, preventing harm to the machine and damage to consumers. Also, some machines come with protective garments, like gloves, goggles, and respirators, to shield people from harmful chemicals and particles.

Polythene bag recycling machines is simple to use, also for newbies, identical to Fosita's product polystyrene granulator machine. To use the machine, start with collecting Polythene bags and sorting them according to their condition and quality. Next, feed the bags into the machine utilizing the appropriate means as device. The machine can process the bags, splitting them to their parts that are constituent like plastic, paper, and steel. Finally, gather the materials that are recycled store them as promote them to recycling organizations.

Fosita a plant with a size of 2,000 square meters situated the romania Advanced Industrial Manufacturing Park. Fosita offers a complete assortment of plastic machinery comprising more than 50 models. The machines meet the demands of clients with regard fill. Our machines are exported over 80 countries around the globe including Middle-East Asia, Africa and South America. Each year, we travel abroad international plastics exhibitions.

Fosita has a range of plastic production lines and machinery.Our primary products are plastic pipe production line plastic profile production line, plastic recycling machine plastic pelletizing equipment and plastic auxiliary machines. Fosita polythene bag recycling machine the manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.

We provide machine polythene bag recycling machine service before delivery. Fosita has a reliable forwarder guarantee machine shipping on time. We offer a entire plastic machine solution within 24 hours. Whether choosing a product from our catalog, or requesting support from our engineers for your project You can speak our customer service team about your requirements for sourcing.

Fosita has high precision equipment and a knowledgeable operator guarantee high quality products. Our experts are on hand answer questions and provide prompt service. Our company accredited through ISO9001,CE,SGS and polythene bag recycling machine. Besides, has 6 patents that are protected by independent intellectual property rights.

To use a Polythene bag recycling machine, follow these basic steps:

1. Gather Polythene bags and sort them according to quality and kind. Eliminate any international items, such as food, paper, as steel.

2. Find the appropriate machine design centered on the recycling requirements and resources available.

3. Install the machine in the region well-ventilated enough room and power.

4. Set up the machine according to the maker's guidelines, ensuring all safety features is practical.

5. Load the Polythene bags into the machine, following suggested means or device.

6. Begin the machine and monitor the recycling process, ensuring safety and effectiveness.

7. Collect the materials that are recycled store them as promote them to recycling organizations.

Polythene bag recycling machines need regular upkeep and servicing to make sure maximised performance and durability, similar to the plastic washing line supplied by Fosita. Maintenance include cleansing, lubrication, and substitution of worn-out parts. Servicing include tech support team, troubleshooting, and improvements. Most manufacturers service offering such as the guarantee, classes, and free parts.

The quality of Polythene bag recycling machines differs with regards to the maker, design, and cost, same with Fosita's wpc foam board machine. Quality machines need robust construction, advanced level technology, and high effectiveness. Also, they are safer, effortless to use, and durable. Before purchasing a machine, it is essential to studies and compare different designs and companies, see customer ratings and ranks, and check certifications and requirements.