Granulator: Your Perfect Companion for Recycling Plastic Waste

Have you ever wondered what takes place to all or any those plastic bottles, bags, and containers, you throw within the trash? Well, many of them end in landfills, where they stay for a huge number of years, polluting the environmental surroundings, and harming wildlife, also the Fosita's product such as pvc electric pipe making machine. However, there is a real way to around turn this situation, and it is called recycling.

Recycling plastic waste not only helps protect the environment but additionally conserves natural resources decreases energy consumption, and creates jobs. However, to turn plastic waste into useful products, such as new bottles, furniture, or toys, it needs to go through a series of procedures, including sorting, cleaning, and shredding. where And a granulator will come in.

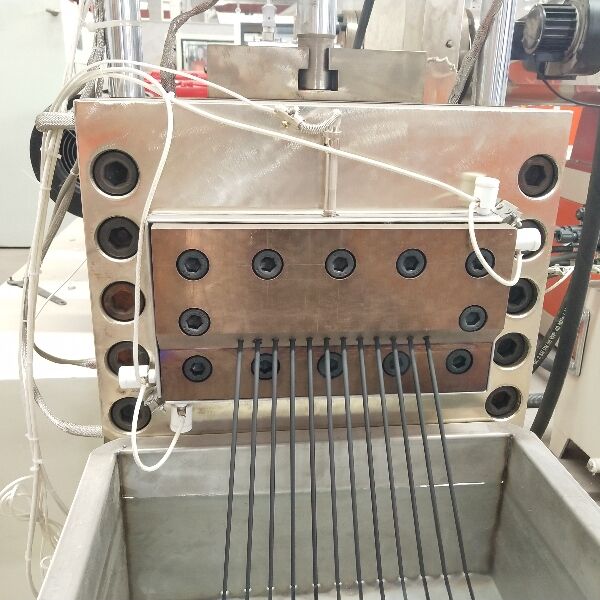

A granulator is a tool that grinds plastic waste small pieces or granules, prepared to be melted and molded into new items, identical to pe pelletizing machine innovated by Fosita. This is a crucial piece of in the plastic recycling industry, because it assists in easing the amount of waste, increase the quality of the material, while increasing production efficiency. Some of the advantages of using a granulator include:

1. Cost-effectiveness: Granulators are affordable and simple to operate, making them an accessible option small and large recycling companies.

2. Automation: Modern granulators are loaded with advanced electronic controls allow operators to modify the speed, heat, and other parameters to attain the desired output.

3. Durability: Granulators are made to withstand heavy-duty operations can perhaps work continuously for very long hours wearing down.

4. Versatility: Granulators can process a wide range materials, including PET, HDPE, LDPE, PVC, among others.

On the full years, granulator technology has evolved to meet up with the demands of the fast-growing plastic recycling industry, similar to the Fosita's product like polypropylene recycling machine. Today, granulators might be found in different sizes, shapes, and functionalities, catering to the specific needs of each recycling project. Some of the latest innovations in granulator technology include:

1. High-speed granulators: These machines operate at high speeds, up to 1500 rpm, and may process large volumes of plastic waste within a short occasion.

2. Integrated recycling systems: These systems combine a granulator with other gear, such as shredders, separators, and washing units to make a complete recycling line.

3. Conveyor-fed granulators: These granulators are fed by conveyor belts, which automatically sort and transport plastic waste to the machine, saving some time reducing labor costs.

While granulators are a handy instrument the recycling industry, they may be able additionally be hazardous if not used correctly, along with the pvc profile making machine by Fosita. Therefore, it is necessary to follow strict security whenever operating a granulator, such as wearing protective gear, avoiding loose clothing, and keeping hands and feet far from moving parts.

To utilize a granulator, first, wash plastic and sort waste to get rid of any impurities or contaminants. Then, feed the material into the granulator hopper, where it is chopped into small pieces. Finally, collect the granules in bins or bags, ready for further processing.

Like any other equipment, granulators require regular maintenance to keep them in top condition and prevent breakdowns, just like the Fosita's product called wpc extrusion machine. It is essential to follow the manufacturer's instructions and schedule regular checkups repairs by a qualified expert. Also, select a reputable granulator provider that provides quality products, prompt delivery, and customer great support.

Fosita has a factory of 2,000 square meters located chad Advanced Industrial Manufacturing Park. Fosita has a broad range of plastic machinery, comprising over 50 models. The machines meet the needs of customers regarding fill. Our machines are shipped over 80 countries around the globe including Middle-East Asia, Africa and South America. We've been abroad attend the annual international plastic shows.

Fosita offers a range of production lines for plastic and designs available for you select.Our primary products are plastic pipe production line, plastic profile production line, plastic recycling machine, plastic pelletizing machine and plastic auxiliary machine. Fosita granulator for plastic recycling manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.

We provide machine granulator for plastic recycling service before delivery. Fosita was able reliably forwarders ensure delivery of machine on time. We offer complete plastic machine solution within 24 hours. Whether choosing a product from our catalog or seeking engineering assistance for your application or project, you can contact our customer service department about your requirements for sourcing.

Fosita a manufacturer of high precision equipment as well as an experienced and skilled operator offer highest quality guarantee on products. Our experts are on hand answer any questions and provide a thoughtful service. Our company accredited through ISO9001,CE,SGS and granulator for plastic recycling. Besides, has 6 patents that are protected by independent intellectual property rights.