Recycle plastic such as a professional with an Industrial plastic recycling machine commercial

Are you aware that tons of plastic waste are produced every day? An abundance of it ends up in the ocean and harms life marine. But, due to the Fosita plastic industrial machine, we could now turn waste plastic into reusable materials. We are going demonstrate exactly what this machine can exactly do and how it will also help us protect the earth.

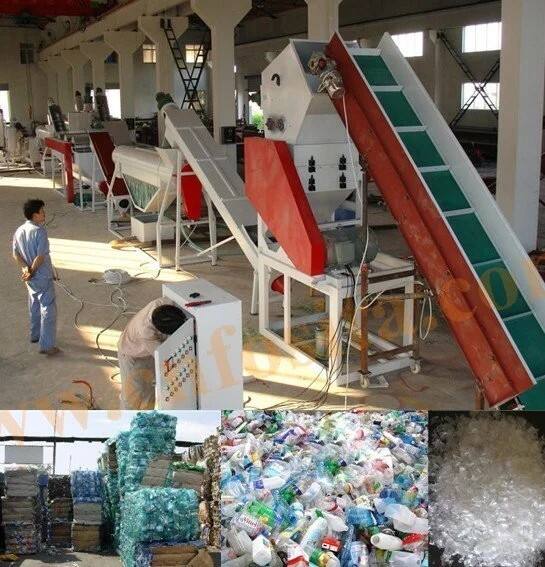

An Industrialplastic recycling machine can shred, grind, melt, and extrude plastic wasteinto pellets. These Fosita plastic shredder machine industrial pellets can be employed create plastic brand new asopposed making utilization of virgin materials. The benefits of using anplastic machine industrial:

1. It decreaseswaste plastic keeps our environment clean.

2. It reduces theuse of virgin materials and saves normal resources.

3. It generates asupply brand new of and employment for people tangled up in wastemanagement.

4. It assistscompanies meet environmental regulations and reduce their carbon footprint.

The Industrialplastic recycling machine Fosita went through a few innovations making it moreefficient and user-friendly. For instance, some industrial plastic shredder machines are designed withsensors that detect and remove contaminants through the waste plasticprocessing. Others have smart settings can adjust the settings with regards thevariety of plastic being recycled. There are additionally devices that couldhandle bulky or hard-to-process waste plastic.

Securityis merely a priority when utilizing an Industrial plastic recycling machine.You need to wear appropriate gear protective such as attention securityand gloves, when handling plastic waste or running the machine. The Fosita industrial plastic recycling machine also needs to be examined for regularly just about any signs of wear or harmthat could cause accidents. Lastly, only trained workers should operate themachine avoid any injuries.

Havingan Industrial plastic recycling machine is simple. First, sort the plasticwaste and take away any materials that are non-plastic such as paper or metal.Then, feed the waste plastic the machine's shredder or grinder. TheFosita machine will probably then process the waste plastic particles that arelittle. Next, the particles is supposed to be melted and extruded into pellets.Finally, the pellets are cooled and capable of being used which will make newservices being plastic.

Fosita boasts high-quality equipment as well as an experienced and skilled operator offer high quality product guarantee. Our experts are on hand answer questions and provide prompt service. Our company accredited through ISO9001,CE,SGS and industrial plastic recycling machine. Besides, has 6 patents that are protected by independent intellectual property rights.

Fosita a plant with a size of 2,000 square meters situated the colombia Advanced Industrial Manufacturing Park. Fosita offers a complete assortment of plastic machinery comprising more than 50 models. The machines meet the demands of clients with regard fill. Our machines are exported over 80 countries around the globe including Middle-East Asia, Africa and South America. Each year, we travel abroad international plastics exhibitions.

We provide machine industrial plastic recycling machine service before delivery. Fosita used a forwarder that was reliable ensure delivery of machine on time. We offer plastic machine solution within 24 hours. Whether choosing a current item from our catalog or seeking engineering assistance for your application, you can talk our customer support center regarding requirements of your sourcing.

Fosita offers a range of plastic machinery production lines and designs choose from.Our main produts are plastic pipe production line, plastic profile production line, plastic recycling machine, plastic pelletizing machine and plastic auxiliary machine. Fosita specialized industrial plastic recycling machine, processing in assembling of plastic extruder technology with professional engineer and sales team.