Ukusho Lwamakhono Amanqaku PVC

Uma ube usethile ukubona umsebenzi ophambili wakhiwo, ungabonanga amanqaku amahhale, amhlabedi esihlangene nezinhlangothi zokuphakama kanye nokuncedisiyo, ngokusho kweFosita's iproduct elichazwe njenge umsebenzi wophrofethi lwe-PP pellets . Amalungu amahlukile amachazwe ngokuthi amaphrotektha ielektroni yamaphrojekti. Amakhono Okusebenza Amalungu PVC Amayithi ayisebenziswayo ukukhetha amalungu amahhale ngokushesha kunye nendlela enomsindo. Izikhono zakhiwo ezisebenza amalungu PVC amayithi zingakwazi ukwenza lokho ngokushesha kunye nokudibana.

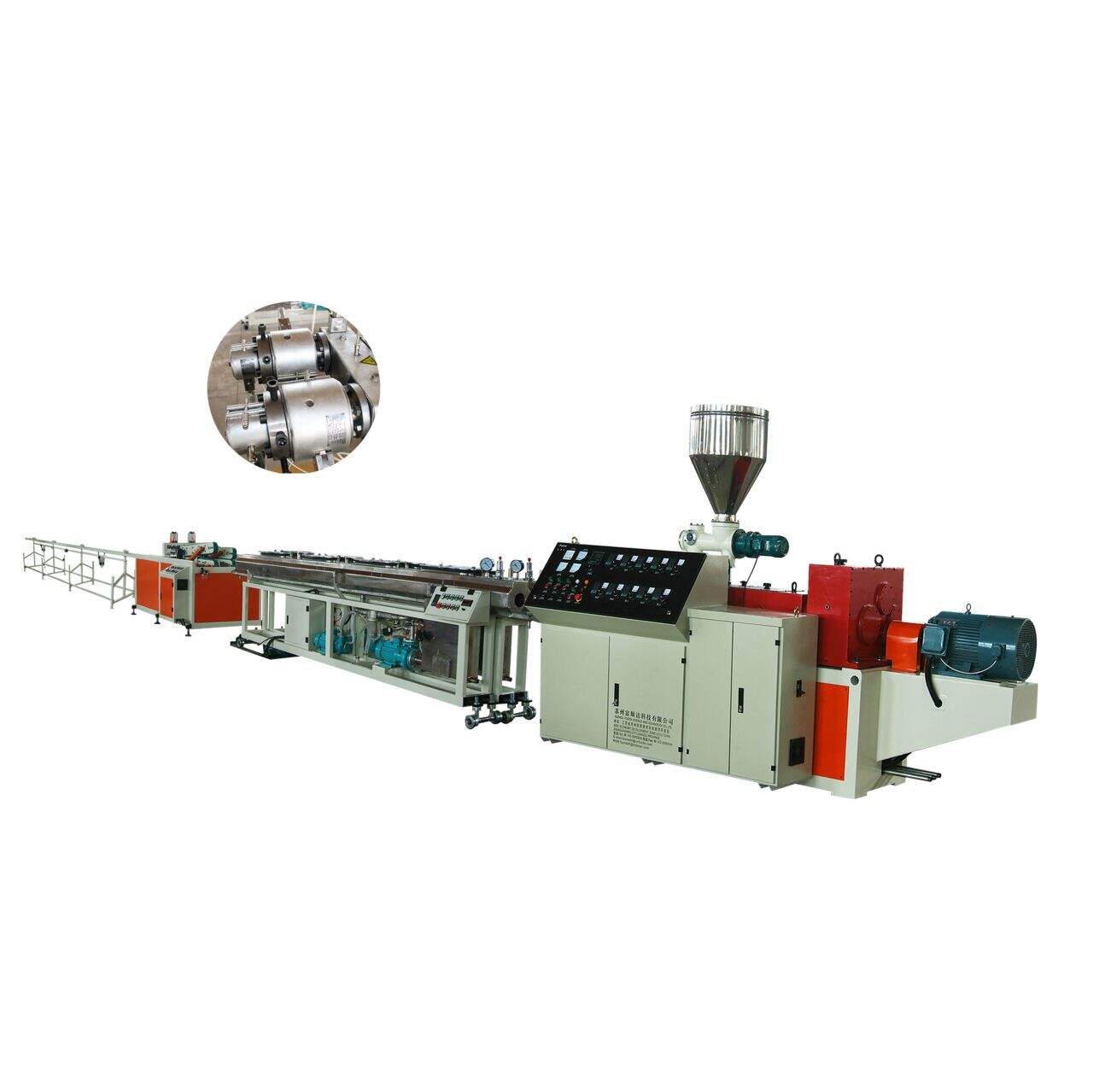

I-PVC Conduit Pipe Making Machine inekhi zimbini ngaphezulu kwezinhlobo zakugcina ezintathu zezidingo zokubutha amandla, njenge plastic profile extrusion equipment ngokwamashumi amabili, kufuneka umoya wokuqala lokuhlala kwayo kubekwe ngendlela eliphezulu kunye nekupheleni okuthile phakathi komphendulo womphendulo. Ngaphandle kokuba imfanele yomphendulo yokusebenza le-PVC Conduit Pipe Making Machine, izindlebe zikhululiwe ngalinye ilimi lokugcina ukusetyenziswa nokusenzenziswa. Emvume wenze izindlebe ezidingekayo ngenqanawe yesiphumo esiqhathanisiweyo. Lokhu kushicilela ukuba zonke izindlebe zidingekayo ngendawo efaneleyo kunye nokuphakamiselo, okuningi lapho lokho kufanele kwiimbiko yemfihlakalo. Ngokwesishiyagalolunye, iimfanele ye-PVC Conduit Pipe Making Machine zinethengiso olungaphakathi kunye nokukhathalelwa. Zingavulwa ngaphandle kwezinto ezifana ngecorosayioni, amakhemikali, kunye nokuhlola, futhi bazibuyelela ukuthi babephindvise ukungavunyelwe emfihlakalini.

Iimfanele ye-PVC Conduit Pipe Making Machine zikhona zikhululekile kakhulu, njenge-produkthi yase-Fosita umsebenzi wophrojekhi yesithelo esesintu . Ukuphatha kwisimbi esisethweni sihlukileyo ukubonisa ukuba imibuzo emisha ayiqondisiwe ngokuthi amashiye amasha amandla kulandelini kunye nokuhlala khuluma. Isimbi esisethweni sisho isisebenzi sesikompiyuthi. Lolu hlobo lokusebenza lushayela abasebenzisi ukusetyenziswa nesikhombiselo sokusebenza kanye nokufinyelela umsebenzi wokususa lapho luhlula. Isimbi esisodwa sisho usenzo lwemilayithi yemilayo. Lolu hlobo lokusebenza lushayela iindlebe zizoba zifundekiwe ngezinto ezimbili, njengokuba zihlukahluku okanye uvambo olungakho.

Ngonyaka ongcinezeka ukuqalasela i-PVC Conduit Pipe Making Machine, uhlelo lwendlela luyahlukele, ngokushesha, njenge umthwalo wokuqinisekiswa kwepapha lePVC owabulawa ngu-Fosita. Abasebenzisi babebona ukusetshenziswa kwesicatshulwa, njengemitha nezinhloso zokugcina, ukusuka iziphiwo. Babelenza ukusetshenziswa kwisebenza kakhulu. Ngokwesiphumo, umasebenzi usebenzisa ngokuqinilekileyo. Abasebenzisi bavume umthombo wesintsi phakathi komasebenzi kwaye bafinyelela umsebenzi wokususa ukusombulula ukuba kuhluke.

Fosita inesithuthi esikhona ngenqanawe nezimali zokungena ukuthi amandla akho ayiqinileyo. Amakhasi akethu abafuneki ukukwazi kuzenza imibuzo kunye nokufinyelela kusenzo sokungena. Lishomi lakethu libhalwe ngendlela ye-ISO9001,CE,SGS kunye nomsebenzi wokubhala amaphayipi a-PVC. Ngakho xa kune 6 amapatente apho amandla angiphindwe ngamalungelo amahluke amandla.

Fosita izinga lokufundzisa le-2,000 imitha elihlukene e Advanced Industrial Manufacturing Park. Fosita ungenxa emfunamanisi wemakhine yephesi, okulandelayo kungenani nge-50 amamodeli. Amakhine angavumelana namagama akhona ngokuthula ukungena. Imikhiqizo yakho zikhishwe ezindaweni ezibhenzeka ngo-80 ngaphandle kwesonto phakathi kwe-Middle-East Asia, Africa nokuma-Amerika. Sifunde ngaphandle kuziphatha izikhelo zokusebenza esisisekelweni somakhine yephesi.

Fosita uphindelela umdloti omfunamanisi wemakhine yephesi futhi amandla ahlukene okungayaziyo okungavunyelwa. Izindlela zakho ezidingekayo zizikhona plastic pipe production lines, plastic profiles production lines, plastic recycling machines, pelletizing machines for plastic nokuxhasa oluncedisiweyo. Fosita iphiko yephesi yokubhala ipipe yephesi, ukuhlanganiswa nokuvikelezela komphilo wesintshontsho wesophethelo sengenziwe ngabanye abasebenzisi abahlukene beseleshi.

Sihlelisa uphawu lwezindlela zokubutha ipaphu le-PVC ngaphambi kokuthiwa. Fosita wakwazi ukwenza amandla kakhulu ukuba abasebenzi bayenze ukuthi iphephandaba libe lapho ngenxa yesikhatsi. Siyibuyekezo yomphawu wophesha phakathi kwe-24 izinsuku. Ngoba uhlola imveliso esikhatsini sethu okungenani noma uvuselela umthondvo wesikhwama, ukungena nomtheleli wethu wesicelo ngalo msebenzi lokuhlola ngalokhu olufunekayo.