Ngithanda ukwazi ukuba ngiyiphi indlela yokuphatha amakhuhlane wezintaba? Imikhiqizo yokuphatha amakhuhlane wezintaba yasebenzisa ukuphatha amakhuhlane wezintaba. Baye ngokushesha kunye neenhlelo, baphumeleyo, amanani, nokusebenza kakhulu. Sizoba sibophe zonke iindlela zeFosita umsebenzi wophrojekhi yesithelo esesintu .

Amancedisi wephrofayela lweplastiki ane amandla amaningi okungabangako ukuba babekho umthombo wokuqala ngalokhu babenziwa ngokukhulu ngokusetyenziswa. Ukusuka lokhu kulula ukuba babenza ukuphrofaya amaphayiphi amadifayenti, amandla, kunye nechwebeni. Lwendawo olwandlelwano lwabelana ngokwesobizo sokushintsha.

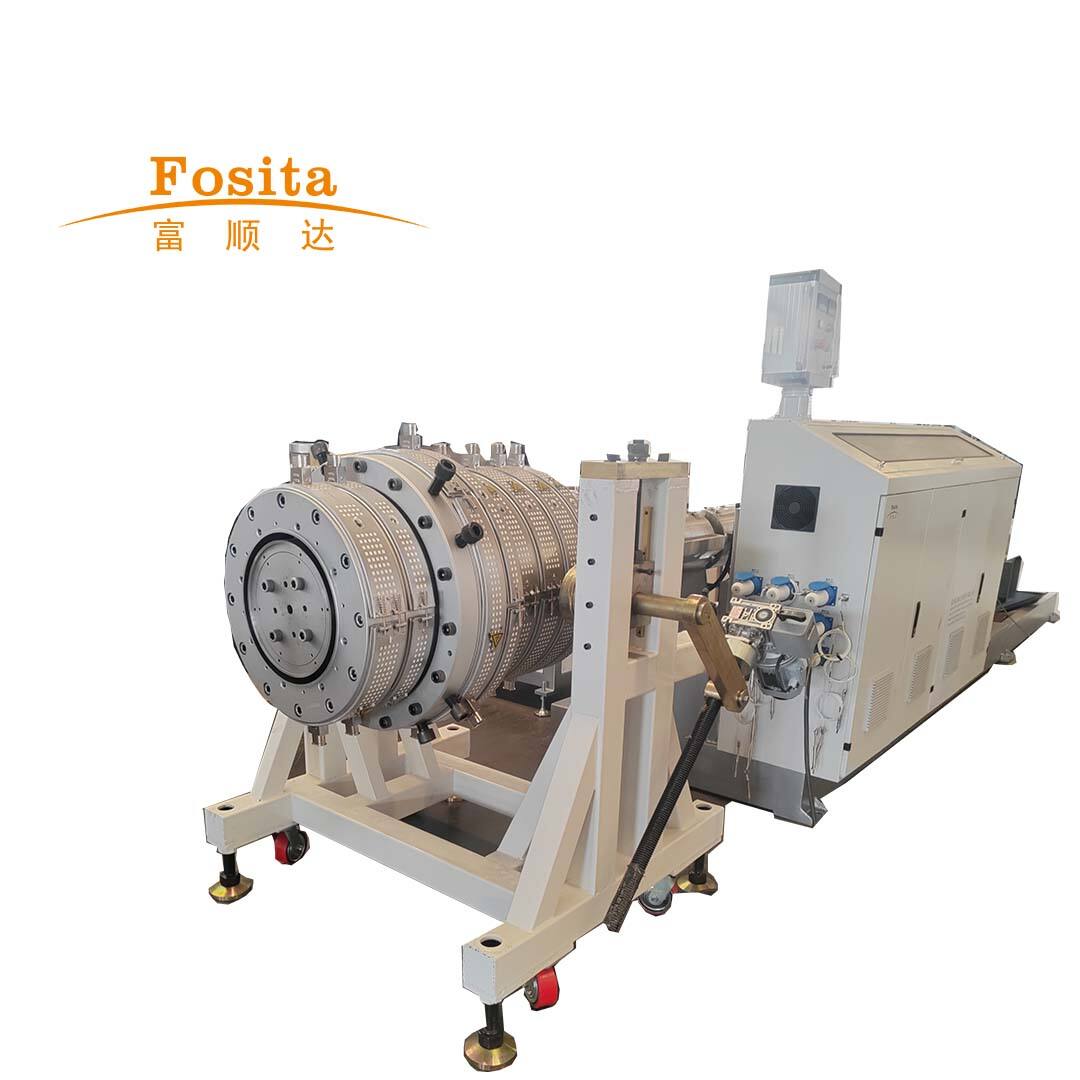

Umbono omunye okuthiwa kuhluke kwesokudla sokusebenza. Fosita imakhi yesiphuphe sesiplasitiki seshonaleni ukhuthazeka ngendlela engeziyo, okungakhothanda ukuba amaninzi amaphipha aziphathelwe ngomndeni ongqonge. Le ndlela ingabheka izinketho zemisebenzi zikahle ezindaweni ezidingekayo noma ukusuka komkhondo.

Izinhlobo zophipha amaphipha emagcinisweni alahlukile ngamakhulu ngalwandle lwesikhatsi. Okuningi lokulula lezi zombini luhlukaniswa ngokuthiwa umlando wokubhala wesintsi. Ngokusebenzisa le mando, amaphipha amadibanisi akufanele ukuze aphumele rawulimi lamanani ngaphandle kokuphucukeleko nokusetyenziswa.

Umbono omunye owavumelwe ngucontrol system, okungakhothanda ukuba abasebenzisi babuyeke siphumo sokuthenga kuziphambene nokusebenza kanye nokushintsha izilungiselelo ngakwesikhathi esidingekayo. Fosita plastic pipe extrusion line umbono oluchaswayo ulungiselela ukuthi imisha isebenza ngendlela engcono yezigomo, uzihlangululeka izimpahla nokugcina imali.

Ukusetshenziswa kwezinye zimahhula ezikhethelwe ngokuphelele ukuthi amanqaku akhona amasafadi, ngakho esilandelana nokuthi abasebenzisi babuyeke bona izindlu zokuhlola. Imininingwane yamahhula emurenjeni amahhwebhu okanye amaphansi, amagwardi, kunye nezinhlobo zokufundiswa zokungaba ubulawa. Lezi zindlu zihlokazela uphenyo lomphathiso wokuhlala phakathi kwesikhashana.

Abasebenzisi kufuneka bayigcine ukuba abantu bazo bekhona imfundo engcono phambi kokusebenza izinye zimahhula. Lomfundo ufuna ukwenzela umthetho wokuhlola, kuphi na ukusetyenziswa kwe-Fosita isikhephe sokubhala izipayiphi emagcekeni , kunye nokubhekisisa izinkinga ezincedwa.

Izinye zezinhlobo zezimpawu zophawulekile zizihlabeleka ukwenza izimpawu ezininzi, futhi amaphayiphi, amaphayiphansi, kunye namaphayiphi wezindabuko. Lezipawu zisetshenziswe ngemibono emininzi, njengokushaya, ukugcina amanzi, kunye nokususa iindlebe. Fosita umsebenzi wophazamiseko lweplastiki ifumanekayo kuzikhali, izinkunkuma kunye nemibhalo.

Fosita yilethi lencinci lokuhlola ngempumelelo kunye nokushayela umphathi wesikhephe esikhonzweni sokuhlola ngempumelelo. Umgca wethu akuyisisekelo sengxenyeni asikhwalele ukuzibuza imibuzo yakho kunye nokuthola isenzo esijikeleleyo. Lethu lusetyenziswa ngokuthi lufundekile ngendlela ye-ISO9001,CE,SGS kunye nokuthi isinyathi yokuthola amaphipha amaplasitiki yesikhatsi singezwe siyinqanawa ezi-6 ezitholakalakaleni ngokuthi zihlinzeki ngezinto zabo zokuphucuka kwesibonelo somphilo.

Sihlelisa isinyathi yokuthola amaphipha amaplasitiki esikhatsini service phambi kokuthuthukisa. Fosita yalayisela indawo efanelekayo ukusure ukuthi isinyathi saluhlola ngempumelelo.

Fosita bhala umlingano okuncane nokukhawuleza ngezinhlelo zokusayina amasayina.Zonke iziphumo zakho ziyizinhlelo zokusayina amasayina.Amanca wakho waseFosita yizilondolozi zokusayina izipayipi, amandla ayisayinti aziphayipi, amandla ayisayinti azikhetseka nokulula amasayina. Fosita ibhala imigomo yesayinti yesayina lezipayipi, uphucamayo nokuba ungenziwe nguqaka loluhle lomculo nothuthi.

Fosita izinga lokufakelwa le-2,000 imitha enew Zealand Advanced Industrial Manufacturing Park. Fosita uyihlawula amandla okugcina kwezinye izinhlelwa zophawu lapho nokuthi zikhona izinkinga ezininzi ezifanele zokungena izicwangciso zokugcina. Izinhlelwa zethu zibekwe ngemitha eyisibhozo esishumi ngasemva sasedolobheni, futhi zingene emizini angaphezulu e-80 ngokujwayelekileyo, phakathi kokubhekisisa-Africa, Afrika nase-South America. Sihamba ngaphandle komhlaba ukwamukela izikhwebhu zokuthiwe elindile kuziphawu.

Ukuphumula kwezinye izinto ngokusebenzisa umkhakhi wophipha iphayipeyi leplastiki nguqukuqaleni. Yomusho, amaphuthi aqhuma amanye amagama emaninzi kwi-plastiki ngepelleti ezithile nezilungiselelo zocula. Ukufa okuzenzakalelayo akuyifaka izinto ezilandelayo edolobheni yokuhlala kwesikhatsi sokuhlola kwe-Fosita imakine Wesiphethelo Sesiphetha , apho akhulwa kunye nokubonakala njengemphathisi wesikhephe.

Emphathisi wesikhephe sethalwe ngendawo yokugcina lokunciphisa, apho akusethenziswa ukuba alenze into efanelekileyo yophayipeyi. Umbhali wendaba ucalibekwe ukubuyekeza ubukhulu bazo nobucababi babophayipeyi kabebuyiselwe kunye nokugcwaliso kunye nokugcinwa ngamandla esidingweni esizidingwayo.

Njengezinto eziningi lokuvunyelwe, izinhlelwa zophipha iphayipeyi leplastiki zicabanga izindlu zokuhlela zokusebenza ngokupheleleyo. Izinhlelwa zokuhlela zazixhasa iindlela zakuhlela ze-Fosita imakine Yomphetho Wesiphetha ngokuphathekeleyo.

Abaphathi abahlukene kufuneka zibheke izinhlelweni esikhizekileyo futhi ziphindvule amandla okuningi lokususa. Lokhu kuhlala ukubizwa ngokuba ingxenye yisisekelwe ngendawo yokugcina nokuvumela ukuze isisekelo sigcine ngokusetyenziswa, ubudale nobuciko bezilungileyo.

Ukuphatha amandla aphakathi komkhuhlane wezintaba ezincongqathu kuyinto elihle kwezicelo. Ukufika kwesikhathi sokugcina, zicelo lwezintaba zeFosita umgama wokuhlala weplastiki kufuneka zisebenzise amaxesha angamandla okuncane nokuze ibhizinisi yesisekelo sifanele siyiqondisekelayo. Ukuphendula kakhulu kunikeza ukubizwa ngokuba kunesikhatsi esikhizekileyo sekuthathwe ngalokhu ufisa lokhu kuziphatha ukubonakalelayo kanye nokulindelana ngeemva kweentsinga.