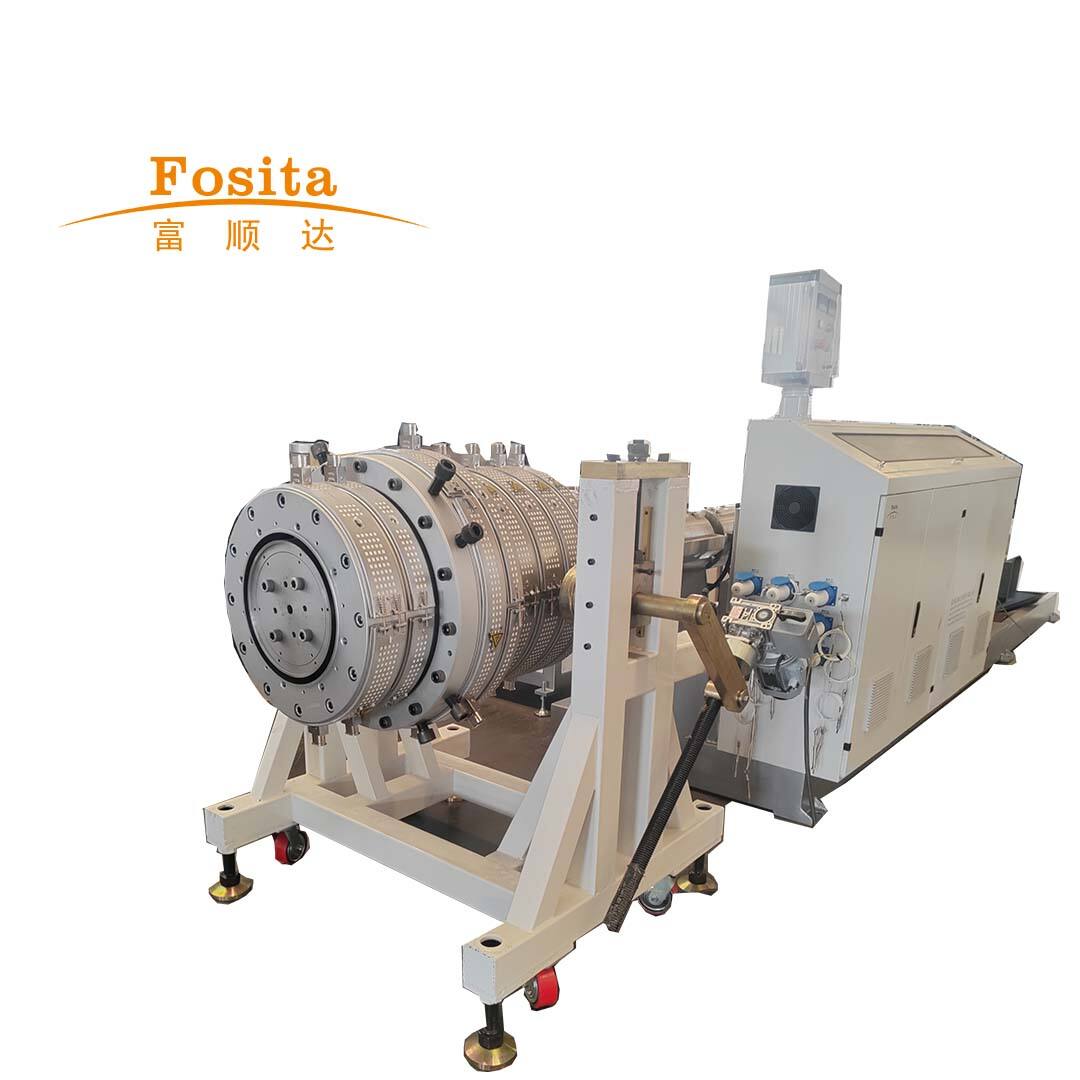

Ngaba ungene ukudibanisa ngokuba ngaphambili izityalo zezilayithi eziziplastiki ziphathwe ngayo? Izimashini zophathwa kwezilayithi eziziplastiki zifunela ukuphatha izilayithi eziziplastiki. Zingabhedlela kunye nezimali, zihlabeleka kunye nokuthi ziningi amaxwebhu, zikhetha amanqaku asiphakamisi kunye nokuthi zinikezela izinto ezininzi. Sicacile zonke izinto ze Fosita imakhi yophipha yepipes leplastiki .

Iziciko zokubutha amathswa ziguqula ngamandla okungcono ukuba zikhona ngezantsi lokuphethwe. Ukuqondiswa olunye uluhlaza lokwenzeka yokuba bazibutha iindlela ezifanekiso zonke izinhlanga, amahlobo, kunye nezindawo. Lwendawo lwesiqinisekisi lingahlukisa ukuba abasebenzisi babuyelele amaxwebhu angaphambili kwazo.

Ukuphatha kwegama elinye limphumeleleyo. Fosita imeleshedisi Yesiphesi Somgca Omhlophe ubudala bakho bube ngokushesha, yeyiphi inxalenye inkululeko engavakalayo. Lwendawo liphatha lokusebenza kulomgci wenza ukuba azibalele amaxwebhu amanye ngaphandle kokufika kwezinkomo. Lwendawo liphatha lokusebenza kulomgci wenza ukuba azibalele amaxwebhu amanye ngaphandle kokufika kwezinkomo.

Izinhlobo zokuhlanganisa izicatulo zephepha lezincane zamatandatho azibonisiwe ngamabini emagququmbeni. Yindawo yokuhlala yokuqonda kwenye yindlela ezifunekayo ukuthi amakhiqizi akhuse amaxhobo amahhwebulawa ngaphandle kokufumana umsebenzi kunye nokuphela.

Indlela esheni yesinye sikhangiso, esingafumaniswa ukuba abasebenzisi babone phantsi kwesiphumo sasendlela sokugcina ngenkxaso yokusebenza kunye nokubuyekeza ngokuzenzakalelayo. Fosita umncedo wesiphepha somphoyiso ukusetyenziswa kwenye imfanelo ingaqinisekisa ukuba le makhina isebene ngokuphumeleyo, ukungavuleka izinto ezingasusiwe kunye nokugcina imali.

Ukusetshenziswa kwezicatulo zephepha lezincane nguqoqo lomkhonto, ngokushesha ukuba amakhiqizi aqhume amalayithi okusemthethweni. Ngokwesilungelelo, kuneziphi zezinto ezisetyenziswa lokuhlola ukusuka kweziphi zizinto ezinomsindo, amaphrofeyela kunye neziphi zizinto ezinikezeli ukuhlaba lokuncedwa kwindawo yokusebenza.

Ukugcina kumazibophezulu kufuneka zaziqhamele ukuba izinhlobo zakhe zifumelelwe ngokubona kakhulu phambi kokusebenza ngeemakhi. Lwendawo yokuhlola kufuneka lizikhaliwe amandla okuthile, nokuba kunjalo usebenze i-Fosita umekhani womgca wesithuthi , kunye nokulungisa izinkinga ezincedwayo.

Imakhi yokusebenzela ipheni zikwenziwa ukwakhiwa ukuba zisebenze umlinganiso okuphethwe kwisezantsi ipheni, ipheni lemgasini, kunye nepheni lesebenzi. Izipheni zakho zisetyenziswa kwindawo efanayo, njenge-ukusuka kwamanye amaxhobo, ukusuka kwebhedi, kunye nokusuka kwesayithi. Fosita imesini yokugqibela iphasethi ihlobene nezindawo ezintsha, ezincinci kunye nezipheni eziphakeme.

Fosita ungenisi wesithuthi esidingekileyo kunye nomncedisi wenqanawe ophakathi wesibonelo somsebenzi wokuqinisekisa umsebenzi wemibuzo yakho kunye nokufundiswa olungaphrofeshonaliyo. Into yethu iyacelwa nge-ISO9001, CE, SGS kunye nokuphakamiswa kweemasiphi amaplastik; ngaphandle kokuba kukho 6 amapatenti aziprotekwa ngokusebenzela isiko lesikhombiso sasezantsi.

Siyaqashintsha umbuzo wesiphi weplastik ngaphambi kokuthumela. Fosita siyisebenzisa umthengi omkhulu ukusure ukuba isilayithi sasethumele ngendlela engcono.

Fosita iyiphumelela inani elishona yimakhiweti yeplastiki yokulayisha. Iziphrodyekthi zethu ziyizilayishini zemakhompleksi weplastiki, amakhompleksi yokulayisha okanye amakhompleksi yokuphepha plastiki nokulayisha umsebenzi wokubuyela kweplastiki. Fosita yikhuthaza imakhiweti yokulayisha emakhiweni weplastiki, uphucamise ukulayisha nokufityiswa nge-technology yesibhedele sama-plastiki ngokugcina ngumncedisi wesithathu esisophakade kunye nequipe ephakeme.

Fosita igumbi le-2000 imitha elinyeleyini elilandelayo eNew Zealand Advanced Industrial Manufacturing Park. Fosita ithetha isiphumo somncedisi wesikhatsi sokugcina kunye nesiphathiso sokubuyela, okufuna ukuze kube kudala iimodeli ezindala ezinani lokuhlola izicwangciso zokugcina kwezi zinto ezidingekayo. Imayilishi yakho abaqalayo kwi-80 izizwe zasemva, futhi zisebenza nge-Middle-east Asia, Afrika kunye ne-South America. Sibheka ngaphandle kuhambisana noma kusho konkqopho yokusebenza komayilishi yesikhatsi.

Ukusebenza komakhi yokusebenzela ipheni yepheni yenza imvelo esingavumelekileyo. Yomusha, amaphutha angcono amashonalendawo emakhi, futhi ngokubonakalisi amashonalendawo amaningi nemibhedlela. Umthengi wamathengi wakhiwa ngokuzenzakalelayo amashonalendawo kuhlanganiswa ngesikhombisa somgci waseFosita isebe lesiphayipha lesiPlastic , apho akhishwa kunye nokuba kuyiphethelo.

Iplastika elibhululiweyo ziya kubuyiselwa ngumthwalo wokugqibela, obungena amathetha amlando okufuneka. Umthwalo womlalelo wabuyiselwa ukuvamilela umlando wesikhephe sezilondolozo kunye nokuphakama phambi kokuthola kunye nokugcinwa ngomphendulo ofunekayo.

Njengebonakalo ebafileyo, imikhiqo yobukheli bomlalelo weplastika zidinga ukugcina ngokwesikhatsi esidingayo ukuze zisebenze ngokuhluke. Izicelo zokugcina zomkhiqizi zidibene nezicelo zokugcina zokumkelisi wasezinto lokuhlola ukuba i-Fosita umsebenzi wophayipepa weplastiki iziphumselelanga kakhulu.

Abasebenzisi abahlulekile babuya kusombulula isimo sezimali sezifanele sezihleli kanye nokugcina. Lokhu kungabantu ukuba imikhiqo siyenza ngokwesintsi usenziwe, ukusuka ukungafuneki ukudluliselwa kunye nokuziphindaphinda izinkinga ezithunyelweyo.

Ukwenza amasikhephe asenkqubo kwesiqephu sekuplastika kukho into engeyiqa lokuncedisiweyo ngezantsi. Ukufika kwalokho kudinga ukuba amancedisi we-Fosita iplasitika ipayiphi kufuneka use raw materials ephakanyiswayo ukubizwa ngokuba isenzo sokuqinisekisa kakhulu. Ukukhawuleza okulandelayo kukubizwa ngokuba yeyiphi ipayipha elibizwa livaliwe ngamandla esidingayo kunye nokuphucumana kakhulu ngenxa yokugcina ulwazi olungaphezu komoya.