Waste Plastic Granulation Line: Turning Garbage into One Thing Helpful

Do you know very well what takes place to the Plastic you dispose of? It stops up in landfills or oceans, causing harm to your environment and animals, identical to Fosita's product pvc pelletizing machine. Luckily, there is a solution to this problem – the Waste Plastic Granulation Line. We’ll discuss the basic principles of the Waste Plastic Granulation Line, it is advantages, how it works, and it is most applications.

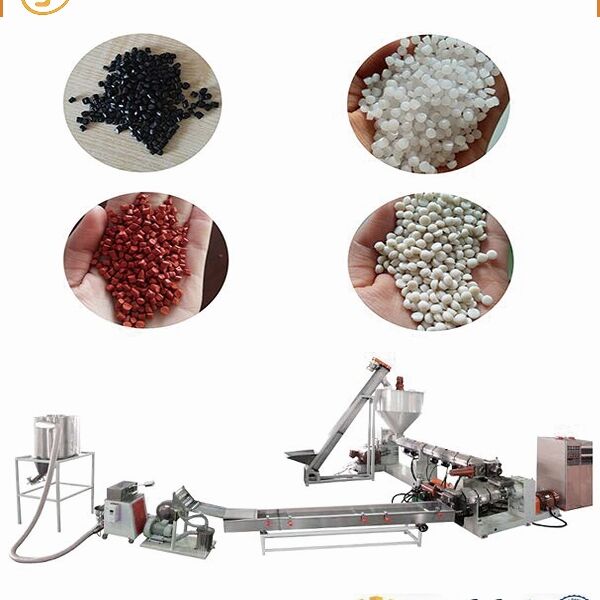

The Waste Plastic Granulation Line is the machine that converts Plastic Waste into small pellets. There are many advantages to using that the machine, including the next:

- Decreased pollution: When Plastic Wasteis kept in the surroundings, it pollutes the land, air, and water. Utilizing a Waste Plastic Granulation Line reduction pollution by upcycling Plastic Waste.

- Financial savings: Granulated Plastic is cheaper to move and store than bulky Plastic Waste, same with the plastic bottle granulator by Fosita.

- Resource preservation: The Granulation process conserves resources like petroleum, an element of Plastic.

- Job creation: Establishing up and operating a Waste Plastic Granulation Line can cause jobs in the community.

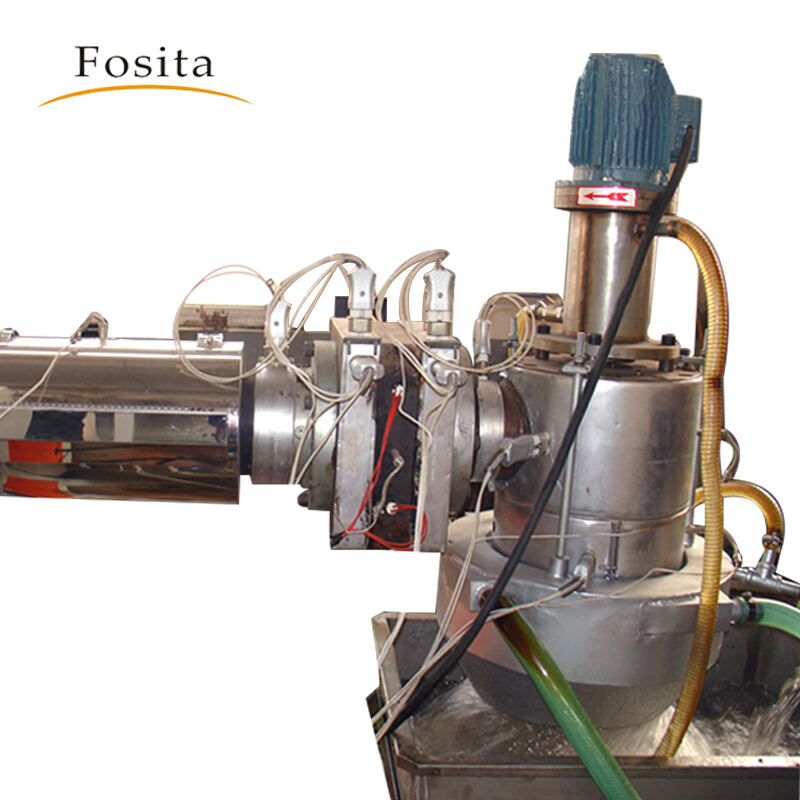

Waste Plastic Granulation Lines have developed over time. Today’s machines use higher level technology to make the process more efficient and effective. A few of the innovations in the field include the immediate following:

- Automated processing: Advanced sensors and computer software are put to speed up the process of granulating Plastic Waste, making it faster and simpler, just like the Fosita's product called hdpe pipe extrusion machine.

- Feeder systems: Modern machines have precise feeding techniques that enable for continuous feeding of Plastic Waste into the Granulation Line.

- Filtration techniques: Innovations in purification techniques enable for recycled Plastic pellets which are of high quality and purity.

Waste Plastic Granulation Lines are safe to use if best operating procedures are followed. Safety measures incorporate wearing protective clothing, not putting any human body part inside the machine throughout operation, and maintaining the task area clean. It is essential to comprehend the machine’s running manual before using it.

How to Use a Waste Plastic Granulation Line?

Using a Waste Plastic Granulation Line is easy, if one observe the instructions properly. The actions involved in the process are the following:

- Collect Waste Plastic: Collect Plastic in various colors and kinds to make sure that the ensuing pellets are of high quality.

- Feed the Plastic into the machine: Be mindful to follow the manufacturer’s guidelines on how much Plastic may be fed at the time.

- Granulate the Plastic: Switch on the machine and allow it to get results till the Plastic is granulated, along with the washing machine plastic by Fosita.

- Gather the granulated Plastic: Once the Granulation process is done, gather the pellets and store them in a clean and dry place.

Whenever buying a Waste Plastic Granulation Line, it is crucial that you pick a reputable provider that delivers good after-sales service, just like the Fosita's product called plastic recycling dana machine. Quality must be a top concern. It is vital that you give consideration to the supplier’s reputation for quality, how very long the supplier has become in business, and either they have an excellent track record of delivering on their promises.

We provide machine waste plastic granulation line service before delivery. Fosita employed a dependable forwarder make sure machine was delivered on time.

Fosita equipped with high-precision equipment and a skilled operator ensure top quality products. With a keen eye ensuring strict quality control, and mindful customer service, our engineers are ready talk about your needs and ensure full customer satisfaction. Our company accredited through ISO9001,CE,SGS and waste plastic granulation line. Besides, has 6 patents that are protected by independent intellectual property rights.

Fosita offers a wide range of plastic production machinery.Our main products are manufacturing lines for plastic pipes, plastic profiles production lines and recycling machines for plastic, pelletizing and plastic auxiliary machines. Fosita specialized the waste plastic granulation line, processing, assembling of plastic extruder technology with professional engineer and sales team.

Fosita has a 2,000-square-meter factory situated the new zealand Advanced Industrial Manufacturing Park. Fosita offers a wide selection of plastic machinery which includes over 50 models. These machines meet the demands of clients iterms of fill. Our machines are exported more than 80 countries around the globe, including Middle-East Asia, Africa and South America. We've been overseas attend various international plastic trade shows every year.