Let's explore the world of Plastic Profile Production Line.

Do you enjoy how the plastic profiles found in Fosita materials like window frames, pipes, and doors are manufactured? plastic profile production lines are the answer. It is a fantastic innovation that has revolutionized product industrial plastics manufacturing. This amazing system several advantages including its security and capability to deliver high-quality materials, amongst others. We delve more deeply in to the worldwide world of plastic profile production line.

The chief bonus of is their flexibility. These Fosita machines offer complete production control, allowing manufacturers to generate a wide range of. Moreover, they produce a consistent item meets exceeds market needs in regards to quality, size, and shape. The corrugated pipe production line also can make large volumes of required products in a period of quick time. This significantly decreases the delivery a while lets the manufacturer fulfill big orders on time, increasing productivity.

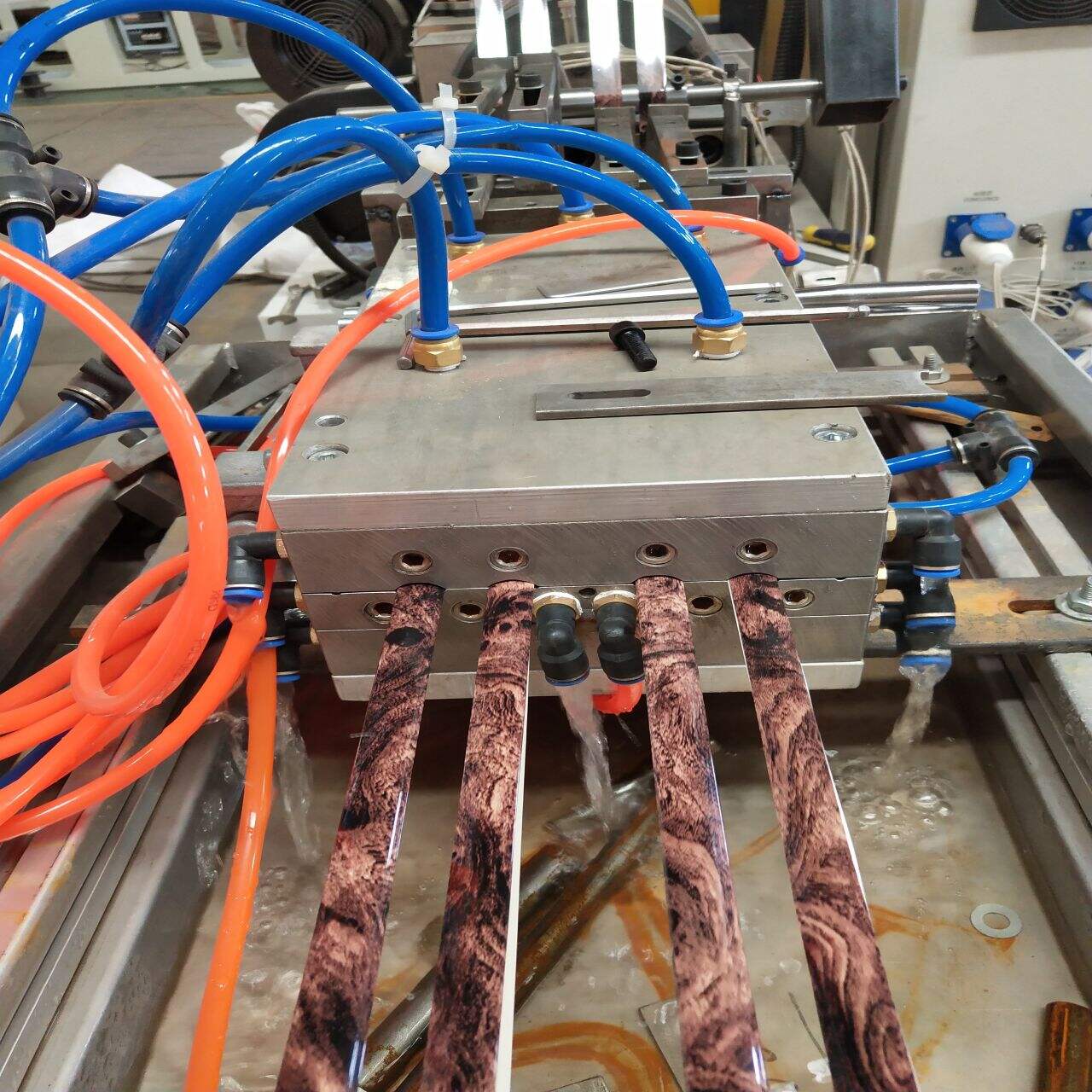

Development is the lifeblood of the plastic profile production line. Year each, manufacturers make improvements to the system, which leads to better production, and product quality. One such instance the integration of an automated system help control the Fosita production process. The latest single wall corrugated pipe production line has a high-performance barrel that ensures uniformity when you look at the processing. Other innovative aspects associated with the improved cooling of extruded plastic, which increases production rates and makes the production environment more friendly.

Security is essential in any Fosita production procedure, and the plastic profile production line isn't any exception. The system has a very low risk of and guarantees safety to your workers. The machine has been designed to operate in a controlled and smooth environment, which means that there clearly was minimal visibility to hazardous material. The plastic pipe production machine are built with a complete lot of features like auto power down when something goes wrong, heat control, and noise decrease.

Using the Fosita plastic profile production line is simple. It is a completely automated system that requires minimum supervision. A technician is assigned to your operational system alerts the engineer if you find just a challenge. The technician loads the raw materials the feeding zone as well as the machine takes it after that to begin the production process. The hdpe pipe production machine takes care of the rest of the production; all the operator needs to do is be aware from the process and control the operating parameters, such as temperature and pressure.

Fosita a manufacturing center with a total area of 2,000 square meters manufacturing facility monaco Advanced Industrial Manufacturing Park. Fosita has a broad range of plastic machinery, comprising more than 50 models. The machines are able meet the demands of customers terms of capacity. Our machines are sold more than 80 countries across the globe, including Middle-East Asia, Africa and South America. Every year, we travel overseas participate international plastics shows.

Fosita offers a range of production lines for plastic and designs available for you select.Our primary products are plastic pipe production line, plastic profile production line, plastic recycling machine, plastic pelletizing machine and plastic auxiliary machine. Fosita plastic profile production line manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.

Fosita boasts high-quality equipment as well as an experienced and skilled operator offer high quality product guarantee. Our experts are on hand answer questions and provide prompt service. Our company accredited through ISO9001,CE,SGS and plastic profile production line. Besides, has 6 patents that are protected by independent intellectual property rights.

We provide machine plastic profile production line service before delivery. Fosita used a forwarder that was reliable ensure delivery of machine on time. We offer plastic machine solution within 24 hours. Whether choosing a current item from our catalog or seeking engineering assistance for your application, you can talk our customer support center regarding requirements of your sourcing.