Are you aware of a versatile and machine that has been intelligent can transform plastic waste into reusable raw materials in a short while? Yes, we are talking about Fosita garden pipe manufacturing machine, a cutting-edge innovation made to protect the environment and save cash. We're going to introduce one for this device that remarkable delve into its benefits, innovation, safety, use, service, quality, and applications.

The plastic granulator equipment has importance several traditional ways of plastic waste disposal. Firstly, it is a solution that eco-friendly because it recycles plastic waste into valuable raw materials that can produce a wide range of products. Secondly, Fosita hdpe pipe extrusion machine decreases landfill waste, conserves resources natural and saves energy and water. Thirdly, it encourages sustainability and supports the economy that circular.

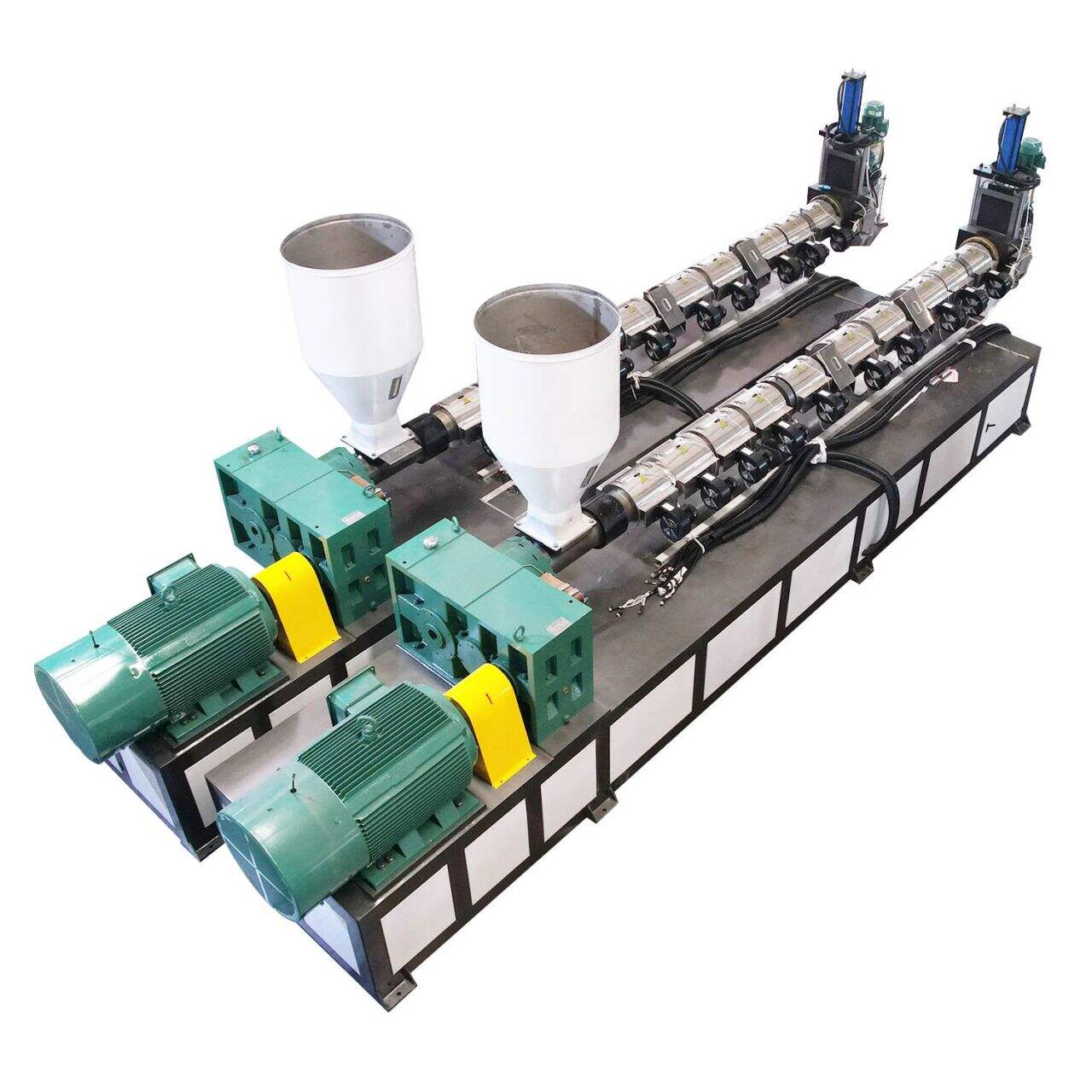

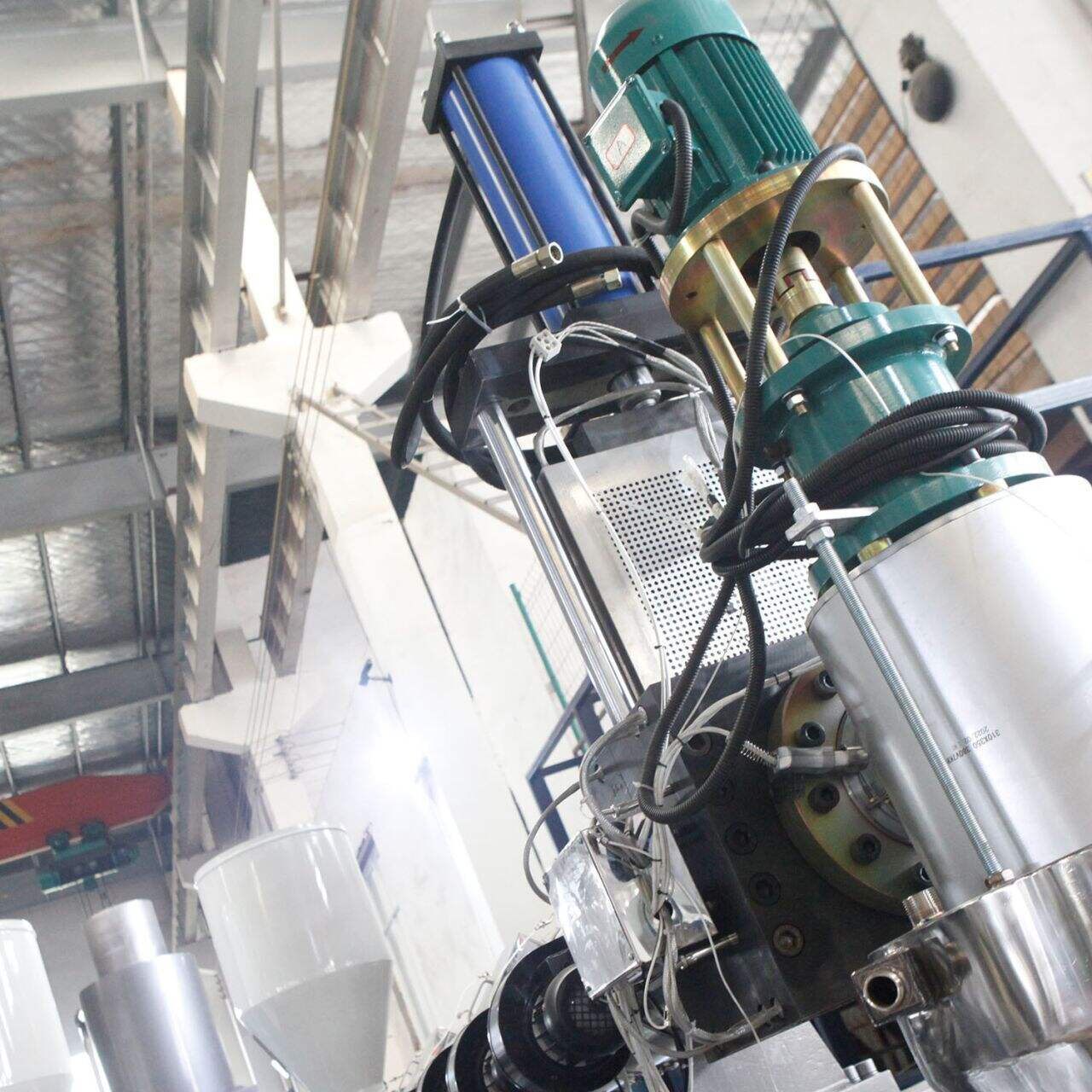

The plastic granulator equipment is a groundbreaking invention that utilizes advanced technology and engineering to grind, shred, and compact waste that plastic. Fosita polyethylene pipe production line boils down in various sizes and designs, from small tabletop machines to large plants industrial and can process all types of plastic items, such as bottles, bags, films, and toys.

The plastic granulator equipment is a safe and tool that reliable operated correctly. Fosita conduit pipe manufacturing machine offers safety features, such as emergency end buttons, interlocking doors, and protection overload to avoid accidents and injuries. It furthermore meets standards international quality and safety.

To make use of the plastic granulator equipment, you must follow some actions basic. Firstly, collect and sort the waste that try plastic homogeneous batches in accordance with their type, size, and color. Secondly, feed the waste that plastic the machine's funnel or conveyor, and adjust the settings based on the desired production size and speed. Thirdly, monitor the Fosita machine for pvc pipe manufacturing performance and empty the collecting bag or bin when full. Finally, clean and maintain the machine regularly to ensure its efficiency and longevity.

We provide machine plastic granulator equipment service before delivery. Fosita had reliablle forwarder ensure that machine will be delivered on time. We offer entire plastic machine solution within 24 hours. Whether choosing a product from our catalog, or requesting technical assistance for your project contact our customer support center regarding your sourcing requirements.

Fosita offers a wide range of plastic production machines.Our primary products are plastic pipe production line plastic profile production line, plastic recycling machine including a pelletizing machine for plastic and plastic auxiliary machine. Fosita plastic granulator equipment the manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.

Fosita boasts high-quality equipment as well as an experienced and skilled operator offer highest quality guarantee on products. Our experts are on hand answer your questions and offer a professional service. Our company accredited through ISO9001,CE,SGS and plastic granulator equipment. Besides, has 6 patents that are protected by independent intellectual property rights.

Fosita has a factory of 2,000 square meters situated mongolia Advanced Industrial Manufacturing Park. Fosita provides a complete line of plastic machinery supply chain including more than 50 models which meet the needs of our customers with regard the fill terms. Our machines are sold over 80 countries around the world, including Middle-east Asia, Africa and South America. We've traveled abroad participate annual international exhibitions of plastic.