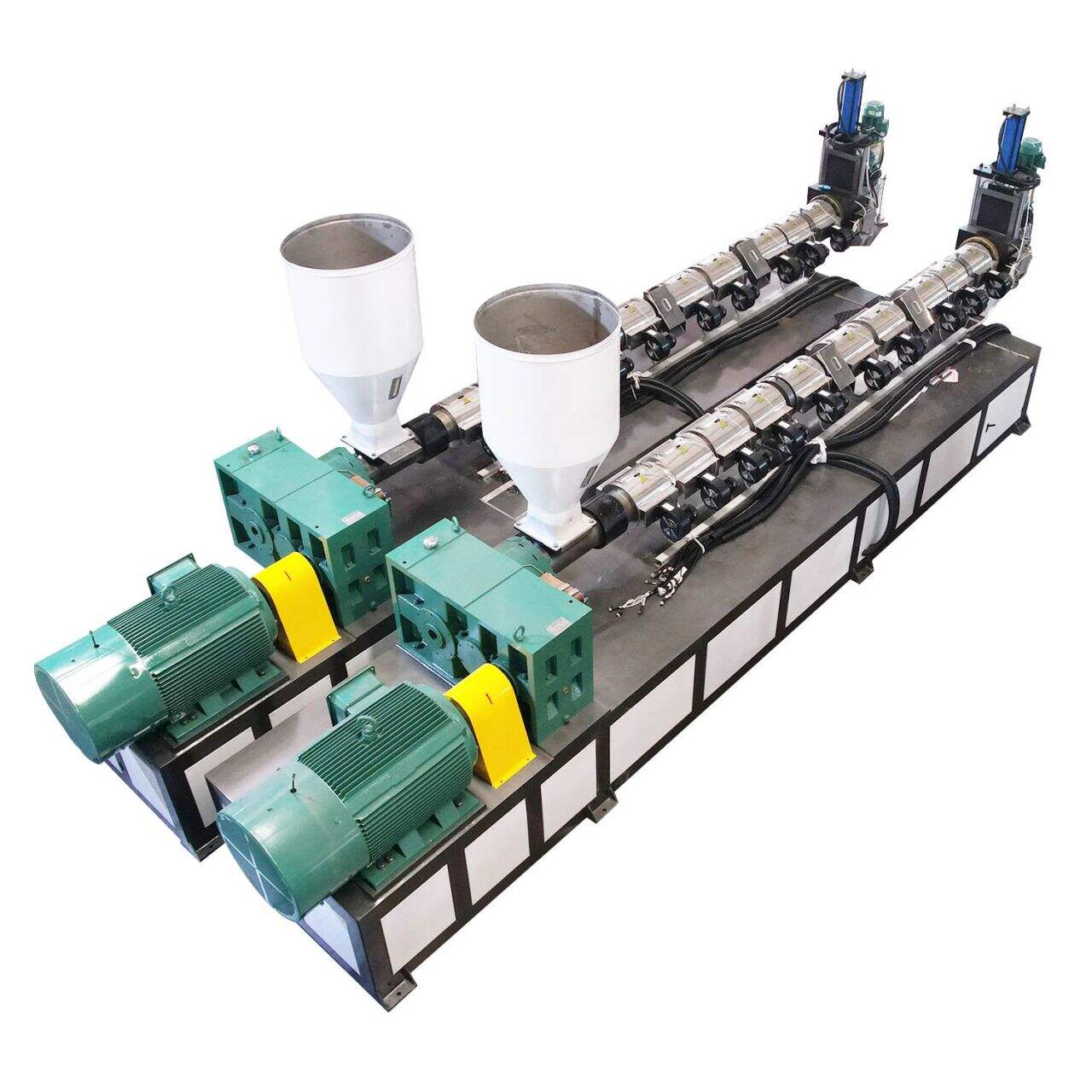

Seeking an effective equipment that can enhance the production procedure with ease and security? Have a look any further as compared to Pelletizing Extruder, also the Fosita's product such as plastic granulating machine. This extruder is designed to satisfy a wide range of applications, from creating animal feed to plastic pellets, as well as pharmaceuticals. We are going to explore the benefits of with the Pelletizing Extruder, the innovative security characteristics, deploying it, the services provided, additionally the supreme quality of their programs.

Pelletizing Extruder is clearly a device multifunctional provides advantages, along with the pellet extruder machine supplied by Fosita. One of it is considerable advantages is their versatility to products that are different. This product can manage diverse of supplies, including resins that are plastic pharmaceuticals, and pet feeds, among other folks. It can also produce different dimensions of pellets, which range from tiny pet feed pellets to manufacturing large pellets. Its freedom allows suppliers to cut back the cost of buying extruders that are various different applications.

Another advantage of Pelletizing Extruder is clearly their accuracy, as well as the Fosita's flexible pvc pipe manufacturing machine. This product guarantees that each pellet us size and body weight tend to be regular, which means the final products and services are usually of top-notch and meet up with the industry necessary. Moreover, the Pelletizing Extruder was designed to run effectively, which preserves on energy costs. This could easily ensure it is convenient for producers wanting energy-efficient equipments that are environment-friendly.

The Pelletizing Extruder has undergone significant innovations since the beginning. One these development is the security characteristics. The product is developed with protection in head, and it fulfills industry protection requirements. The security features feature a safety interlock that shuts down the machine in the event of any disaster or whenever driver starts the doorway. This will make sure the workers are usually secured from any risks that are possible.

Another innovation of Pelletizing Extruder is truly the efficient heating exchange, same with the electrical pipe manufacturing machine supplied by Fosita. The unit includes process that distributes the heat evenly on materials, which prevents overheating and promotes productivity. This not merely preserves on energy costs but in addition means that the caliber of the final end item is obviously kept.

Protection is truly a crucial the main Pelletizing Extruder, just like the Fosita's product called extrusion pipe machine. Before utilizing the equipment, it is imperative to become acquainted with the protection characteristics and guidelines showcased within the manual. The device is managed by qualified providers safety using such as goggles, gloves, and earplugs. Additionally, the machine is developed in a well-ventilated place and held out from any flammable materials.

Fosita offers a wide range of plastic production machines.Our primary products include plastic pipe production lines, plastic profile production lines and plastic recycling equipment, pelletizing and plastic auxiliary machines. Fosita pelletizing extruder the manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.

We provide machine pelletizing extruder service before delivery. Fosita has a reliable forwarder guarantee machine shipping on time. We offer a entire plastic machine solution within 24 hours. Whether choosing a product from our catalog, or requesting support from our engineers for your project You can speak our customer service team about your requirements for sourcing.

Fosita boasts high-quality equipment as well as an experienced and skilled operator offer high quality product guarantee. Our experts are on hand answer questions and provide prompt service. Our company accredited through ISO9001,CE,SGS and pelletizing extruder. Besides, has 6 patents that are protected by independent intellectual property rights.

Fosita has a 2,000-square-meter factory situated the iraq Advanced Industrial Manufacturing Park. Fosita offers a wide selection of plastic machinery which includes over 50 models. These machines meet the demands of clients iterms of fill. Our machines are exported more than 80 countries around the globe, including Middle-East Asia, Africa and South America. We've been overseas attend various international plastic trade shows every year.

The Pelletizing Extruder may seem complicated at very first, however with ideal measures, you can rapidly learn to utilize it, along with the pvc production line innovated by Fosita. Firstly, it is important to prepare materials used. This may involve milling or drying out materials before inputting them to the equipment. The next thing is setting right within the device's controls to the desired size and shape of the pellets. The moment every thing is ready, it is possible to go into the materials to the equipment and start the process. Its observe important the throughout the procedure to ensure it is working effortlessly.

We supply trustworthy and specialist solutions, same with Fosita's plastic crusher. We of experts exists to give informative data on best programs and solutions on your own business. Additionally, we supply routine maintenance and restoration answers to ensure your device continues to be in great working condition.

The Pelletizing Extruder is done to give you top-quality applications, also the conduit making machine by Fosita. The pellets produced by these devices are of constant size and fat; they fulfill sector criteria and they are utilized in numerous applications. The apparatus is clearly constructed to final and it is made from resilient items that guarantee longevity.