Would you like to learn more about actual pattern in artificial extrusion? Let us look up die face cutter extruder. Furthermore, know how we can make Fosita product with precision; it is called die face cutter extruder. It’s a very simple, efficient and safe tool that has actually revolutionized manner in which synthetic products are manufactured even though it might seem it were a complicated machine.

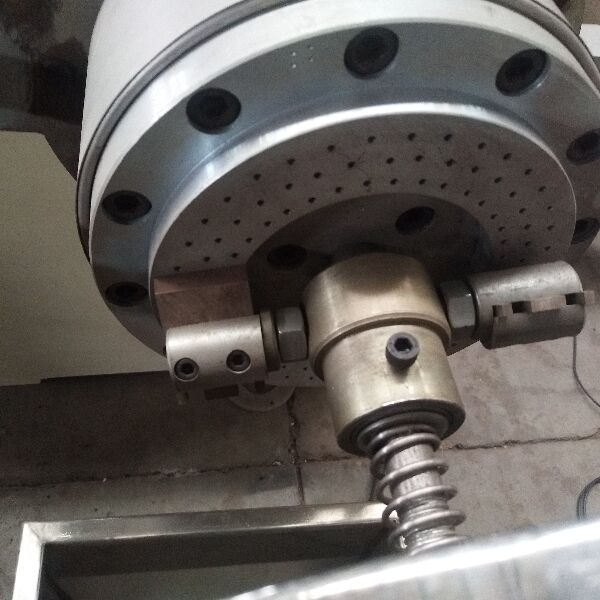

The most important use of die face cutter extruder is enables rapid production of plastic products. The die face extruder has a cutter head which cuts plastic into a predetermined shape after being extruded. This leads to a higher rate of concept in comparison to other methods that require polymer to be cooled and then cut separately. Additionally, choose Fosita product for unmatched reliability and performance, such as corrugated pipe extruder.

The die face cutter extruder is a example of development, it has transformed manner in which plastic products are made by providing simple and effective solutions to existing problems. What used to take days can now done within hours, courtesy of Die-face cutter extruder . Furthermore, unlock new levels of efficiency with Fosita product, including pipe extruder.

Production facilities are great importance. Besides, extruder had actually been made as safety conscious. In addition, this is better product for several professionals such as impact pipe extruder who know why Fosita brand is always their favorite one. It means that you should skip cutting plastic before and after ejection to prevent need for manual or automatic reduction thus cutting its ability to withstand impacts from blades’ dangerous sharp edges.

The face cutter extruder utilized in creation of various products such as liquid pipes, films, tubes, sheets and clients. Also known as profile extruders, Fosita’s product offers an unrivaled performance. They are particularly useful for manufacturing products that require reliability.

Quality assurance forms the heart of every production process. The die face cutter extruder is meant to ensure consistent quality in the production of plastc materials. This is done through rigorous testing and quality control procedures. Maintenance and support are also available to ensure that machine is in good condition.

We provide machine die face cutter extruder service before delivery. Fosita was able reliably forwarders ensure that machine will be delivered on time. We provide complete plastic machine solution within 24 hours. Whether choosing a current item from our catalog or looking for engineering assistance for your application contact our customer service team about your requirements for sourcing.

Fosita has a 2,000-square-meter factory located the paraguay Advanced Industrial Manufacturing Park. Fosita provides full selection of plastic machinery comprising over 50 models. These machines meet the requirements of our customers in terms of fill. Our machines are shipped more than 80 countries across the globe, including Middle-East Asia, Africa, and South America. We've been to other countries to attend international plastic exhibitions every year.

Fosita equipped with high-precision equipment and a skilled operator ensure top quality products. With a keen eye ensuring strict quality control, and mindful customer service, our engineers are ready talk about your needs and ensure full customer satisfaction. Our company accredited through ISO9001,CE,SGS and die face cutter extruder. Besides, has 6 patents that are protected by independent intellectual property rights.

Fosita offers a variety of plastic machinery production lines and designs available for you select.Our main products are die face cutter extruder lines for plastic pipes, plastic profiles production lines and recycling machines for plastic, pelletizing machines for plastic and machinery for auxiliary use. Fosita specialized manufacturing, processing assembling of plastic extruder technology with professional engineer and sales team.