Sibentile: Umphathi Wamandla Wakho Ukubuyisela Izinyathelo Zokuhlola Iplastiki

Ngizoba ukuthi ungaba ungenziwa ntoni edla kulo msebenzi wabantu ababini? pvc electric pipe making machine . Kodwa, kunezinto ezinhle ngaphandle kokuthiwe ukuba lento, kunye nokuhlola.

Ukushintsha amaplastikhi esihlawuliwe ayishayamakhono okulandelayo akhokho lokungena izinkozo, kuzokubonisa iindlela zokuphatha amanqaku, futhi kuhlanganisa ukuhlola kwezilondolozi, kanye nokukhetha umsebenzi. Kodwa, ukusebenzisa amaplastiki esihlawuliwe njengamanani amahlawuliwe, amaboobo, noma amatoyiweyo, kufanele libe liphumeleyo ngumlando wesinye singakwazi ukususa, ukulula, kunye nokugcina. Futhi kunene isebenzelo sokuqinisekiswa.

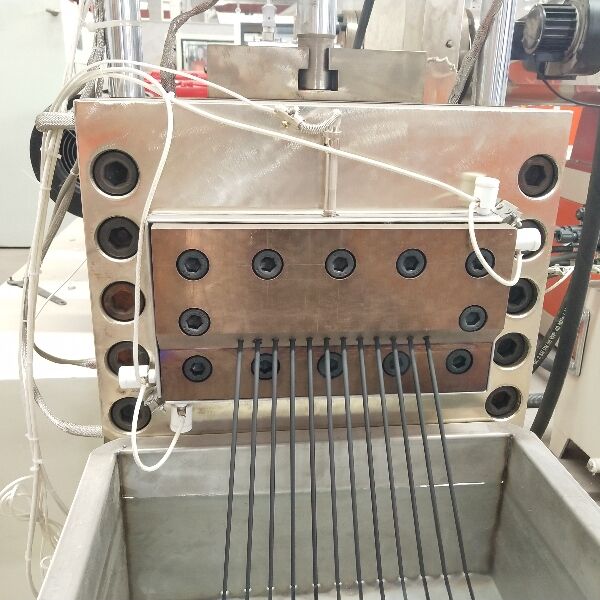

Igranulator yiindlela eyenza ukubhukuda plastiki oluhlukene ngemisebenzi okunyuziwe njengepahla okanye imininingwane, fumanekayo ukuba lihlanganyelwe ukuze lizihlabeleke kulapho lilandelwe kunye nokubhaliswa ngokushesha emuva kwento yokugcina, ngokushesha pe pelletizing imisha ukuthiwa ngokushesha nguFosita. Lento yile yiyingxenye elikhulu kwisekhono sasendlela lokuhlola umnandi wemayisini, ngoba lesi sikophu ukusuka ukuthula okulandelana nokuphucula okubonakali bomncedo, futhi ukuthola ukuhlawula komkhakha wesikweletu. Amahlobo amabili okusebenzela ukusetshenziswa kwegranulelareyo kube ne:

1. Ukungena kakhulu: Ama-granulator ayiqinisekisi kakhulu kunjalo nasebenzi esingaphambili ukuthiwelela, uzame ukuba lento lingalindelelanga emibhaleni yezilungileyo ezincane nezingqanawa.

2. Ukugcina ngokuzenzekelayo: Ama-granulator amandla amodern angavunyelwe amabhizinisi amacala amakhulu okudingeka iziphumo zombusi ukuba zisetshenziswa ispeed, intemba, kunye namagama amanye atholakalayo ukuthola uphawu olufanelekileyo.

3. Ukudlala: Ama-granulator angathathwa ukuba zihlale kakhulu ngendlela engamadoda odladleni kakhulu kunjalo bese bangahlala ngempela ngomoya omncane okuyindlela engazixhasa.

4. Ukuphinda-phindela: Ama-granulator angasetshenziswa ukwasetshenziswa umnandi owenani lodwa, ubuchaze PET, HDPE, LDPE, PVC, kunye namaningi.

Ngemva kokudala kweminyaka, utekonoloji yesiGranulator yesetshenziswa ukuba libe ngokuthuthukise ukuba libe ngokuthiwelela imigomo yendlela yesikhathi sokuhlola umnandi wemayisini, njengokuFosita kuphela umsebenzi wokuhlola ipolipropilini . Lolu hlobo lwesikhashana langesiyo sokuqala, kungakho abaningi amasayizi, amashethelo, kunye noma amaninzi okufuneka lokuhlola ukuthi ubone ngaphandle kokubonisa lokusebenza kwezilayiswano ezidingekayo. Zingaba zonke izibukiso ezintsha ezikhoyo lokusebenza kwezilayiswano ezidingekayo:

1. Umkhomboti wokulayisha oluhlola kakhulu: Izimayile zisebenza ehlola kakhulu, ngokushesha 1500 rpm, futhi zingabonisa ivolayem niyambatho kakhulu yephenethi elihle ngaphambi komhla.

2. Amasistimu akhawulezekile: Izilayiswano zakhiwa nokugcina nezinye iindlela, njengamashreda, amaseparitha, kunye namahlayisheni wezisele, ukwenza umlando omphumeleyo wesilayiswano.

3. Umkhomboti wokulayisha olusetyenzisiwe ngamakhonzi: Izilayiswano zisetshenziswa ngamakhonzi, okusetshenziswa ngokuzenzela nokuthuthukisa uphenethi phakathi kwesikhatsi esikhulu, usave isikhatsi kunye nokuphucula imali yokusebenzela.

Ngakho ke, izilayiswano zihlabeleka ngokukhangelwa lokusebenzela, kodwa zingakwazi ukuba nguyindlela engcono ukubona ngaphandle kokubonisa lokusebenza lokusebenza kwezilayiswano, kunye ne iphi shini yokugcina iprofile yepvc ngokwesihloko sikaFosita. Ngakho ke, kufuneka uzame ukugcina isenzo esincane lokusekela ngenxa yokusebenza ngokuphiweleleyo kwisebenti, njengokubhala amabheshu amaphantsi, ukusukelwa iintsima ezinomsindo kunye nokufaka imilondolozi yamanje xa zisebenza.

Ukusebenza kwisebenti, phambili, shiswa iphetha futhi bomva umoya wemali ukuze ususe anye into engaziqhaweni okanye izinto ezifana nezikhungo. Ngokushesha, thumbe umlando wesintsha kuhhopha lesibentile lapho lichaswa kumakhathaleni onguqhukeni. Phambi kokuthi uphume, chitha amagranule emakhomphini okanye amabhokisi abamabili, amandla kuqaleka ukuba zisetyenziswa ngokulandelayo.

Njengezinto eziphakeme, zingene zisebenza ngokuphiweleleyo ukuba zibe ngokutshontshonge kunye nokuziphindaphinda ukusuka, njengesibentile sikaFosita esiyaziwa wpc extrusion machine . Kufuneka ubuyeke umthetho wokusetyenziswa wesibentile kunye nokususa ukubheka amaphrojekthi amaphantsi amaphandle kwemvelo olungaphindaphinde. Futhi, khetha umbhokisi wesibentile osilandelayo ohlola amandla, uhluke amandla, kunye nokungaphendulekayo kakhulu.

Fosita iyishintsha lesi-2,000 imitha yemetro elihluhleni le Advanced Industrial Manufacturing Park. Fosita inombolo ongashumi ne-50 ngezinhlobo zomkhopho wamaphlastikhi. Izinhlobo ezifanekiso zingabizwa ukuthi zibhekise izidingo zokufaka kwezi zilungileyo. Iziphethelo zinakwenzeka emiphi lemi-80 izizwe ngasemva kwesiphephandaba, phakathi kwe-Middle-East Asia, Afrika nokuma-Amerika Kusasa. Sibuyele esinye sibuyeleyo iindaba zakho zokusebenza komkhopho wesiphephandaba.

Fosita inohlola isihloko esikhulu kwezilini zokusebenza kweplastiki nezinhlela ezifanelekayo okungavumelekanga ukukhetha.Amanca wakho amaphrodyekti wesintuthuko kulandelayo ngokwesobizo phastika, umlinde weplastiki, umkhondo womthengi weplastiki, umkhondo wophulisa plastiki kunye nomkhondo omnyama weplastiki. Fosita granulator yomthengi weplastiki yokusebenzela nokuphatha nokusetyenziswa komphendisi omncane kunye nemakhadhibha akhona.

Sihambisana ngegranulator yomthengi weplastiki yokubuyisela phambi kokuthumela. Fosita wayezibophelela izindlela ezincinci zokuthumela ukuthi imfane woqaphele lemachine lizozalwa nelinyeleyo. Siyithetha isenzo sokuqinisekisa kweplastiki emva kokusha 24 izinsuku. Ngokusho ukuba uhlala uphinde ukukhetha isixhasa sesobizo sethu noma usenza ukufinyelela nokubheka lokunxibelelwa lokho kunjalo, ungathemba nokuthi uzame ukuxoxa ngekhonishoni lakho lokususa ngokuthi ulayishwe ngazo iimeyileyo.

Fosita, umnqwelo wokuhlela amandla okanye umncedisi omkhulu nokuthuthukiseni, uvume ukuphatha kakhulu kwezinto ezilungileyo. Amakhasimakhe amanani akho abesekelwa ukuyibala izicatshululo kunye nokufakela isenzo esidingeni. Lapho yethu ibhizinisiwe ngamalili aseISO9001,CE,SGS kunye nokugcina i-granulator ehlukene ngeplastiki. Ngaphandle kokwabo, kuna 6 amapatenti ayiprotektiwe ngamandla yakwi-intellectual property.