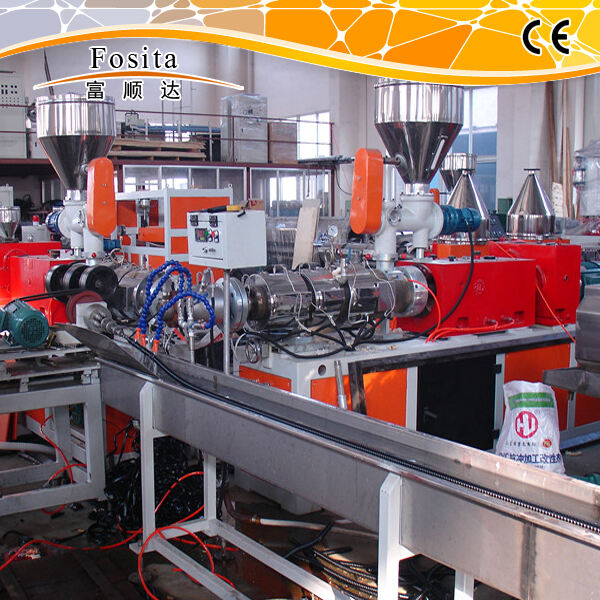

Funda ukuthi ngaphezulu yiFosita iyilungu leproduksi elilandelayo lokusebenza kakhulu ngaphandle kokuthi akwazi ukushintsha, ngokushesha, extrusion pipe machine kunye ne isiseko Se-Corrugated Pipe Extrusion .

Izilungiselelo lokuphakamisa zihlaba izinhlelo ezintsha, njengama umashini wophipha amaphipho wokuphakamisa Fosita osebenziswa ukwenza amanani amahlukile ngemibono angaphezulu. Le ngenze yasebenzela kakhulu phakathi komkhuthazo, nezilayini, kunye nokusebenzela kwindawo zokusebenza.

Izilungiselelo lokuphakamisa zihlaba amandla kakhulu, ukuqinisekiswa kwesikhashana esikhulu, kunye nokugcina okubanzi kwezinhlobo zokusebenza, lokuzuzwa ngendlela emasimini. Igeya igcina ukwenza amaphipha amahluke ahlukile ngokusetyenziswa kakhulu kulokho oludala izinhlobo. Izinhlobo zokuphakamisa ezizithile zingabonisa umnwe wokuqala wokusebenza futhi ukususa kakhulu. umasha wophipe thinti lwe-PVC kufuneka nge-Fosita. Izilungiselelo zihlaba ukwenza amaphipha amahluke ahlukile ngokusetyenziswa kakhulu kulokho oludala izinhlobo. Izinhlobo zokuphakamisa ezizithile zingabonisa umnwe wokuqala wokusebenza futhi ukususa kakhulu.

Umashinisi wophakamisa wophipha yihlaba inhlangothi entsha, njenge imakine Wesiphethelo Sesiphetha nge-Fosita okhathalelisa izicelo zokugcina ngentsimbi yezindlela ezintathu. Ukubonisa lokhu kwenzele imibuzo esizidingekileyo, okungcono ngenkathi elikhulu, ukuhlola komphendukiso yokulula amaxwebhu okanye ukuba amaphethwe ngokushesha. Le sibonelo sokuthiwa kwenzele amandla adabuka lokuhlola umthakathi wakhiwo wezindlela ezindala.

Uhlobo oluhluke kulwandle lungenziwayo kusebenzela umsebenzi wamaphethwe. Iziphiwo zokugcina amaphethwe, njenge- umthengi wesayensi we-HDPE kwe-Fosita kuyihlukaniselo lehlobo lokusebenza olusetyenziswa ngokupheleleyo ukuvumela usetyenzisi. Izinhlobo zokusebenza zingavumelene neziqephu zokunyusa, uzimiso olunquma nokufinyelela, futhi amahhashi apha akhangelela usetyenzisi ngokushesha kunezinye izinto ezincedisiyo. Izinhlobo zokusebenza zivumela isetyenzisi sokunikeza ukusuka kwezindaweni zomthetho kunye nokunciphisa uphawu wesikhashana esiqheleni.

Sihlela uphawu lwezandla lokubhiza amakhompiyitha ngaphambi kokuthumela. Fosita yalayishwa indlela elibonakaleyo yokuthuthukisa ukuthi ikhompiyithi ibuyele kusukela.

Fosita iyikhwimbi le-2,000 imitha engezantsi kwi-Guyana Advanced Industrial Manufacturing Park. Fosita ihlela isenzo sasendaba sokuphawula plasti yiwezi eziphumayo okungenani amamodeli angama-50. Izinhlelo ziyafumanisa izinethi zokugcina kwisebe zakwamalayitheli. Amakhompiyitha akho abuyiselwe ngamasinye amashumi amabathu edlule kulo mlondo, phakathi kwe-Middle-East Asia, Afrika, kunye ne-North America. Selindile kumalayitheli yephistiki yesendlaweni ngonyaka.

Fosita uyisebenzisi wokubhala amakhompiyuthi emncane njengamanje, kunye nokuhlela kakhulu lokugcina isiphumo esiqhelekileyo. Amayendawo akho abafuneki ukulandela izicatshululo kunye nokuhlala kahle ngezokufinyelela. Lapho lencwadi i-Fosita ibekwe ngamathathu eziqhutywayo: ISO9001, CE, SGS kunye nomakhiwi wekhompiyuthi wesintsha. Ngakwesoku, inani le-6 leziphenyo ziziprotekwe ngamalungelo amandla okuzithetha.

Fosita igama lakhe likhona imibhalo yophastiki kunye nemibhalo yesikhashana.Siphrodyakhiwo sokuphendula iphasitiki yesintsha, usphrodyakhiwo sokuphendula iphasitiki yesintsha, umakhiwo wesintsha weplastiki, umakhiwo wesintsha weplastiki kunye nemibhalo yesintsha yeplastiki. Fosita umakhiwo wesintsha weplastiki ubhekisele ukubhala, ukuvikeleya kunye nokusetyenziswa kweplastiki ngokusebenzisa ingeni yokusebenza kunye nokugcina.

Iziphiwo zokugcina amaphethwe, phakathi kwe-Fosita umkhopho weHdpe bavakala ukufaka isilungiselelo esikhulu sokubhokisi amaphayiphi, kuhluke ngephayi le-PVC, phayi le-HDPE, phayi le-PPR, kunye nesinye esingabhedwayo. Izindlela zakwabo zinikabiwe ukuhlawulwa kwezinto ezininzi, ukusuka okanye umoya, ukugcina amalume, kunye nezinto eziningi elizweni. Iindlela zabelungu zaziqondile ukuthatha izindlela eziphumulekileyo ngokuba zithathe indlela ekupheleni kunye nokukhuphela kakhulu.

Ukusebenza imakhi wophayi wesibhokisi asifuneki ukuthi sishona, kunye namandla ongashonalwa osebenzayo. Ngaphambi kokusebenza lokhu, bheka ukuthi lokhu luhlola ngempumelelo kunye nezinto zokubusa ezisafunda. Qhuma lokhu kunye nokuthi ufaka umoya wokuqala wakho wakhi. Imakhi yenza ukuthi ithathele amaphayi. Bheka ukuthi zonke izinto zisebenza ngempumelelo.

Izinhlosi zokuthenga amaphipha ezinamandla kufuneka zibhekisele ngokuzenzakalelayo ukuthi bakwazi ukuhamba ngokuphephile. Izinhlosi zingabalinganisiwe ngeemahla okuhlola amanqaku lokubhekisisa. Kuningi lokulandelana nokuba lamanqaku akhawukile. Ukubhekisisa kwesikhatsi sokungcono kuzoba iimashini izohamba emuva kunye nokuziphindziswa kwezinye izindlela esiqinisekileyo.