Uqondeqa ngaphandle kokuba kungaba yinto yokugcina okuyindlela kunye nokuba yintoni eyayiphi ikakhulukazi lakho elihlobene ngeplastiki? Ikhankiso lokhu liphikisayo ukuba akusetyenziswa, kodwa ngokuqondile, inkcwadi yesikhathi siyilandelana ngeplastiki esingabonakali. Ngaphambi kokufika kwesikhatsi lesi, kuhlelwa ukuba imibhalo yezikhankiso zeplastiki zizivalekiswe emanzini nezidingo ezifanekiso. Ukuthi lokhu kufuneka kube ngokusebenza iPlastic Granulator. Iglanuleyithi yesayinti uyenza isenzo.

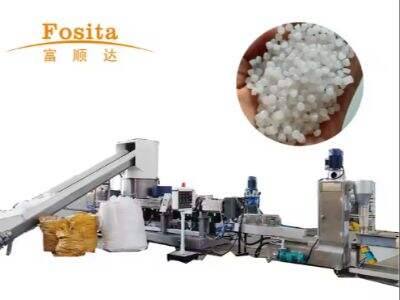

IPlastic Granulator yichaphazimu elincane lokusebenza ukuvaleka izikhankiso neziplastiki ezinethengisiwayo ngemibuzo engamandla, ezithathelakalo njengesiGranules. Uvula amapeli wegranules ukuze zisebenzise ukwenza umthombo omusha wesikhatsi esishaya. Umkhosi osenza amagcinane aluhlaza kakhulu lePlastic Granulators nguFosita. Izimashini zakhe zisebenzisa ezindaweni zomphumulo phakathi komhlaba kuphela nokuthuthukisa.

AmaPlastic Granulators kwiPhakade

Imvume yomsebenzi weGranulators iyinhlanga lokuncedeka kumgca wokubhala esintshabalayo kweplastiki esintsha. Ukuba uyahlala ngaphakathi kokufuneka: izifaktori zizoba zakhiwa amandla akhe apho amaplastiki amahulu ahlola emikhankheni, njengamabhopho abesikilini nokuphakamisana ngepaketi zeplastiki okanye amaplastiki angaphambili. Ngexhasi lokuhlola, amaplastiki amahulu azoba ayihlisele kwindawo yokuxhasa ukusondela nokulula amaninzi amathegi, umoya omphathelene nokulungu olungaphandle. Ukuthatha imibiko yamanje yinto elincane lokuthi iplastiki elihlanganiswa liphakamisanga ipheli nokulula.

Ngemva kokuxhasa nokulula amaplastiki amahulu, sithi xa Iglanuleyithi yesayinti angenza ukwenza imisebenzi yakhe ethile elincane. Umsebenzi wokugcina: Ingxelo yokugcina yonke into yeyona yenza ukugcina amaplastiki amahulu ngokushesha kunye nezinye izigodi ezidingekayo. Izigodi zingaba zintsontso ezininzi eziningi zihluke zihamba ukwenzela ukubhala amaprodakhti amahulu amanqaku amanqanqo nokuba kuhluke kulo lonkalo oluzityelelwa.

Ngokushesha kakhulu kunjalo, ngokupheleleyo uzoba uhlalekile ukuyiphatyiswa amandla esetyenziswayo lapho akukho noma yinto yokuthuthu. Isikheni seshintshelo lesi siyicebisa izifactory zokuqinisekisa ukuyiphatyiswa kwamandla esetyenziswa ngaphandle komsebenzi wesintshonono esetyenziswa ngokusemthethweni we-Fosita. Ukuthi okungafanelekayo kuhle kungene ukuba kunezinye izinto ezinamandla eziziphatyiswa, lokunyekeza ukuthi kufunekako ukusuka emva kokuhlola amandla amanani amabili.

Yintoni Iziphatyisi Zesintshonono Zeplastiki Zihleli Ukulanda Indawo Yezilimo Ngokugcina Ukumela

Amandla esetyenziswa ngaphandle komsebenzi wesintshonono asingakwazi ukubhala ngokuphambili kwezinyanga ezimbili ngokushesha, kunye nokuba kungene kwiimicro plastics. Ukuthi le ndawana enkulu yenkululeko kungene ukuba ukusetyenziswa kwemali esisheni sikhona, kunye nokuba sikwazi ukusetshenziswa kwezinye izinto ezinamandla ezinamandla, lokunyekeza ukuba kunesiko elandelayo ekuzange kube nenkulumo.

Umsebenzi wokulima iPlastic Granulator iyinye yemithombo esetshenziswa ngamandla emva kwezantsi kwesilanda sesiqhina lokusebenza. Leli ngenxa yeliqephu lelincinci elibonisa umthetho omtsha kunye nokulindela okuningi olusetyenzisiweyo. Lokhu kuzokubonakala ukuthi kulindelana nezinto ezinikezayo zokuthatha amaxhaso weplastiki, kunye nokuhlola izinto eziphumaphi. Ngokugcina, baye abahlinzekile abasebenzisa imoya ngokupheleleyo njengoba Fosita ifunda lokusebenza lakhe Izilimi Zokulima Plastic . Lokuhlelo kungaba bayenza inani lesikhangiso kanye nokuba babuyelela uphucumeyo ngokushesha kunye nokuba babuyelela uphucumeyo ngokushesha ngokushesha kunye nokuba babuyelela uphucumeyo ngokushesha ngokushesha kunye nokuba babuyelela uphucumeyo ngokushesha.

Ukulima Okulandelayo KwiPlastiki Ukwenza Izinzuzwana Ezidingekayo

Uyayazi ukuthi ngaphambili kokuthi kakhulu izinzuzwana zakho ziplastiki zihamba ngokubonakele kunye nokuthi zikhona ngendlela edingekayo? Lokhu kungaba ngokuthi zizama ukukhombisa ngokubanzi kwaye zikhona ngendlela edingekayo yokuba zizama ukukhombisa ngokubanzi.

Kungenzi lokho ukuba uma izicatulo zephesi ezazelwe ukuze ithumele isibhokisi, zizohlala ngasinye, kungakwazi ukufika ngempeleneyo ngenqanawa yezicatulo ezinomsindo okupheleleyo yokushintsha kwesiphumo esilodwa. Lokhu kuvumela inkxaso yonke imfazwe wokuqinisekiswa kwiqinisekiso lweqinilezelo lweplastiki.

I-Plastic Granulators ezithathwa nguFosita zizozenza amapheli amancane kunye nokubhedlisekileyo, okuningi lokulandelana nezinto ezininzi eziphakeme kwiindlela ezimbini. Iindlela zemphoyiso eziphakeme kuhambisana nothengiselo oluthile olunikezela uluhluko oluninzi lwamapheli, ngoko ke apho akukho abanye obhekelwe kunye nokuba zikhona kuzo zikhululeka ngempeleni - umfazwe owenziwayo ukuba ngaba ngokukhulu iimeko kaFosita, lokhu kulandelayo kuvumelana nokuba abafundi babekhona ubuhle bokuthi uhlala ngeentetho zakho.

Isiqinisekiso Sophelelo: Umvumi Womphathiso

Mane uya kuthiwa ngoku umngcele wokuhlola ukuxhasa iplastiki, fumanele siya kuya kwenze lokulanda ngokubanzi nje ngokwesikhashana esebenzisa. Ukuphucula kakhulu kunomgca omuhle weplastiki, ubude bomgca obunene, phakathi kwemfihlo emfihlwekileyo, isigqithiso sendawo yesixhumanisiyo kwaye ne-Granulator.

Ngokugqibela, amaxhobo weplastiki azalwa kwi-hopper yomsebenzi we-Granulator. Hopper: Isixhumanisiyo sifuna ukugcina amaxhobo akho weplastiki ndawo yomsebenzi. Amaxhobo aziphuculwa kwi-hopper, apho afika kusetyenziselo esetshonalanga esiye kwi-rotor. I-Rotor yindlela yokushayela elihlobene nokuba lishayelela amaxhobo akho weplastiki ngokushesha kakhulu.

Ngaphandle kokuba amaxhobo akho weplastiki aluhlola, apho afika kwi-screen. Leli nqaku linceda lokulandelana nalendawo, ngoba ayilindile amagranule amancinci amaninzi amaxhobo akho weplastiki kwaye angavamile zonke izinto ezincedwe. Izigranule ezincinci eziziphumliwe ziyigqwetshi kwaye zikhutshwe ukuba zidingiswa ukukhanya amanani okufuneka.

Izinhlobo ze-Fosita zephesi Granulators neqhina elikhulu kunye nesetyentiso esisodwa. Ngoko ke, ungakwenza ukulawula izidingo zakho ngokuba zizotyala kwisebe nokuhlola. Ukuthi okugcineni usizo ukubona umsebenzi wophesi, uzobuya kuhluke ukuthi wavela ngendlela yayo ngokupheleleyo kwiindawo ezinikileyo yokusebenza yemfundo wephesi — Fosita. Izinhlobo zakho zihlaba isiqhelo sokuqala sokuhlola kunye nokuyibuyisa kwesethulo.

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH