Isilondolo sesiPlastiki somkhulu esingazange: Ukubuyisela iGarabi kuNgeniso Elifundekayo

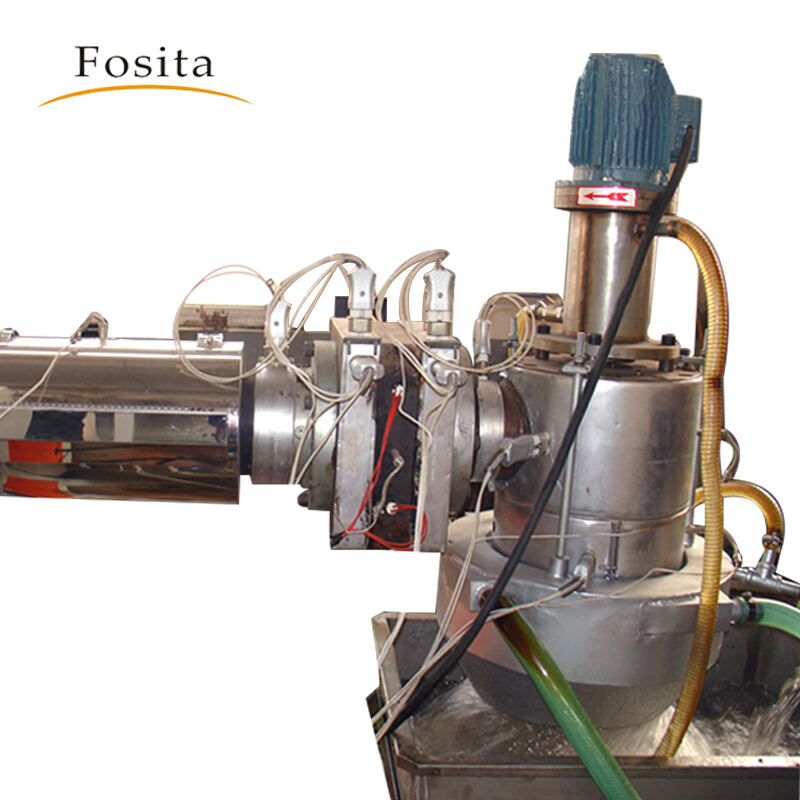

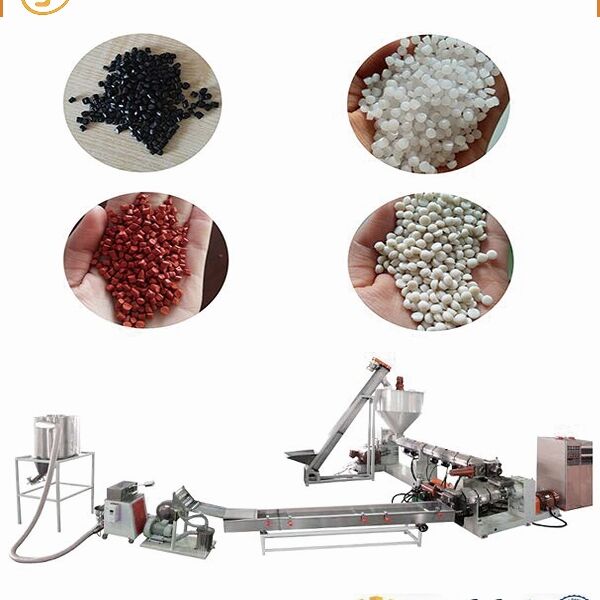

Uyayazi ukuthi ubani obungena lokhu lavela kwiPlastiki usuthengi? Iziphuhliso zihamba ezindaweni zemanzini noma amakhaya, uzama ukusiphakatsa isiqembu senkondo kunye namahlala, ngokushesha kokuba kwiFosita's product ipelatayithi le-PVC . Ngokubhaleke, kunezinto engenza ukulandela le nto – i-Waste Plastic Granulation Line. Zizozibona izicwangciso ezifundazwe zesi-Waste Plastic Granulation Line, amagugu akho, uncedo lwakhe, kunye nolwazi olungaphezulu lwamaphrojekthi yawo.

Isigaba somgca wokubuyisela Iplastiki esiqhelekileyo yimakhiyi apha okuba kuhlukele iPlastiki esiqhelekileyo ngemibala embili. Kunezinye izinkinga zokusebenzisa imakhiyi, ngokusho phambi kokho:

- Ukuphumelela ukusenteka: Ukuba iPlastiki esiqhelekileyo sihamba esendaweni, isentekisa ilandelayo, umoya nokumoya. Ukusebenza iSigaba somgca wokubuyisela Iplastiki esiqhelekileyo kuphumelela ukusenteka ngokuba kunyusa iPlastiki esiqhelekileyo.

- Ukukhubaza amali: IPlastiki elihlukeneyo kukho kuhlukeyo ukuthiwe ngenqanawe kunye nekhaphethelo kancinci nalokuba iPlastiki esiqhelekileyo, njenge- iplastiki yobhoteli elihlukeneyo ngokufaka kwiFosita.

- Ukugcina iziphumo zomoya: Umthengiso wokubuyiswa wakugcina iziphumo zomoya njengepetroli, iphondo lePlastiki.

- Ukwenza izindlela ezimbini: Ukusetshenziswa nokusebenzisa iSigaba somgca wokubuyisela Iplastiki esiqhelekileyo kungabonisa izindlela ezimbini emdeni.

Izindlela zokubuyela kwePlastiki Lelinye lishoqisiwe ngalokulanda. Ngosuku lapho, iimeyi efunyanwa yasebenzisa umthetho wemvelo ofanele ukwenzakalo lokusebenza kwaye kufanele. Zonke izibophelelo ezintsha ezikhona kwiqhobo lapho:

- Ukusebenza ngokuzenzakalelayo: Amasensha amacabanga nokuphucumana kompyutha zisetshenziswa ukuze ziphumelele isimo sokubuyela kwePlastiki Elindile, uzisebenza ngokuphandleni kunye neziqiniso, njengeFosita's iproduct ifanelekile hdpe pipe extrusion machine .

- Izixhobo zokugcwalisa: Iimeyi emodern yasebenzisa amandla amancane yokugcwaliswa okuvumela ukugcwaliswa ngokushesha kwesiPlastiki Esilindileyo ngezindlela zokubuyela.

- Izindlela zokuphinda-phindi: Izibophelelo ezintsha zokuphinda-phindi zivumela ukuba amabhopho webhiya elidibaniswe yasePlastiki ayikho noma yizinto ezincinci.

Izindlela zokulingana ngePlastic Plastic Granulation Lines zingabona ukusetyenziswa kuneendlela ezikhulu zokusebenza. Izicatshulwa zokuqinisekisa zifakile ukusetshenziswa kwezicathulo, ukungavumela ukufaka isigcino semntu ngaphakathi kwebhukompi egxileyo ngemvume yokusebenza, kunye nokuhlinza indawo yomsebenzi ngokuthandwa. Kufuneka ulungiselelwe ukuba ufunda i-manual yesikhephe sengxelo somsebenzi phambi kokusebenzisa.

Ngubani ukusebenzisa i-Waste Plastic Granulation Line?

Ukusebenzisa i-Waste Plastic Granulation Line ingasinye, uma umntu uhlaleke amandla kakhulu. Iindlela ezidingekayo zihlala ngamanye amaxesha:

- Bheka iWaste Plastic: Bheka iPlastic emibeni nezilimi ezininzi ukusure ukuba amaphelane angazixhaswe ngokukhoyo.

- Faka iPlastic kubhukompi: Qonda ukuba ufola amanani akhona amaphi aqhubekayo ngalokhu ofundisiweyo wamanani.

- Xhasa iPlastic: Hlula bhukompi bese uyithumele ukuba le ndlela ngokuvamile xa iPlastic ixhasiwe, ngenxa ye- washing machine plastic ngokufaka kwiFosita.

- Cula amagranuleyo omkhulu wePlastiki: Ngokushesha sokuthi umsebenzi wokugranulula kwenzele, cula amapeli nehlanganise kumgca engenileyo nokuxhaswe.

Kulesi sikhathi sokuthenga Isilondolo sesiPlastiki somkhulu esingazange, kufuneka uzame ukuphinda ngenkxaso enomthetho yokugcina okanyeleyo elibizwa njengeFosita's product called umgca wokuqhathanisa amagqabi kwezivakalelo lomphathisi . Ukuchepha kufunekako kwindawo yasekuhlawuliweyo. Kufuneka uzame ukubona indawo yokusebenza yokugqibela lokusebenzisa ngokuwawu, kunye nokuba ziyazi ukuthi zithi izinkxaso zabo zincedise izidingo zakho.

Siyisebenzisa umsebenzi wophethelo lwezivakasi ezifumanekayo ngaphambi kokuthumela. Fosita usebenzisa umncedisi owamile ukusebenza ngendawo apho iminiko yasebenzise ngemva kokucaciselo kwesikhashana.

Fosita inxalenye yesithuthi esidingene kunye nomncedisi omkhulu osebenzisa amaxesha akhona ukusebenzisa izinto eziphumaphi. Ngenkatho yokubheka amandla, kunye nokuziphatha kakhulu kwezimali, abanye abahlala abafuneka babaluleke ukukumbula ngeendaba zakho kunye nokuhlola ukusasimangaliso kakhulu. Inkompani yakho ibhalwe ngokuthi i-ISO9001,CE,SGS kunye nokuphetha phakathi kwezivakasi ezifumanekayo. Ngaphandle, kukhonjwa ngamaxesha amashumi amane ekhutshelekileyo ngokwesobizo sokuqinisekiswa.

Fosita inqubela umbuso omncane wezinto zokusebenza lokuhlola amaqhawu.Amanje athetha amaxwebhu okulandelwayo lwezilondolozi zamaqhawu, izilondolozi zokusebenzisa amaqhawu, imikhiqizo yeplastikiyo, ipelitayizi leplastikiyo neziphathiso ezincedayo. Fosita yakho yokuvumelaniswa yindlela yokuphakamisela amaqhawu waste plastic, ukuthatha, nokuhlanganisa umthetho wokuxhasa olunyelelwa ngeengenini nemibuzo.

Fosita iyiqhina le-2000 imitha eneenkonzo ehlulekileyo eNew Zealand Advanced Industrial Manufacturing Park. Fosita inqubela iseleksi esidingi kunye nezinye izindlela ezihluhleni eliphethweyo lokuhlola amaqhawu, efuna ukuqala ngokuqala kwezi zintlanu. Izinhlobo zakho zikhishwe ngemigomo emangini wokusasa, futhi akhishwe ngemigomo engu-80 ngaphandle komhlaba, phakathi kokuthi Afrika, Asia-Middle East, nokuba Afrika neNtlatya-Amerika. Siyazi kwindawo zokuthenga ngokwesobizo esilandelayo ngalenyanga.