Did you ever wonder what really happens to your discarded plastic? It sounds like it vanishes into thin air, but in actuality, is recycled to become new plastic products. Before this occurs, however the plastic waste needs to be processed into small and uniform pieces. This is where a specific type of machinery known as the Plastic Granulator comes into play.

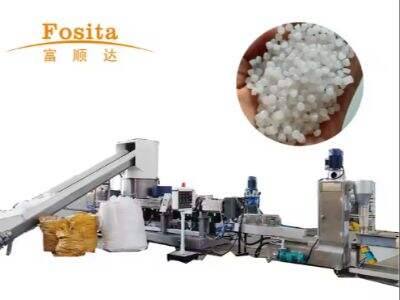

The plastic Granulator is a very powerful machine that works to grind the waste and unwanted plastics into small pieces, called as granules. It melts the pellets and turns them into a new plastic product. One company that produces high quality plastic Granulators is Fosita. Their machines are used in factories across the globe assisting with recycling.

Plastic Granulators in Manufacturing

The role of plastic Granulators is critical in the manufacturing process of new plastics. Here is how it works: factories first gather plastic waste from various locations, like bottles for drinks and food packaging or other plastics. Once it is picked up, the plastic waste goes through a machine process to sort and clean out any dirt, food or other items that people might have put in. The most crucial step in this is to guarantee that the recycled plastic material retrieved possess complete safety and cleanliness.

After sorting and cleaning the plastic waste, it is now time for Plastic Granulator to start doing its other important work. Granulator: The function of the Granulator is to grind the plastic waste into small and same sized shape granules. These granules are then used to manufacture new plastic products like furniture, toys, and everything else that we use on a daily basis.

We will be able to recycle plastic waste only with great difficulty and in very much longer time if we have no any help from a tool like this. This machine allows factories to recycle the waste generated through Fosita's plastic Granulators in a fast and efficient manner. This in turn means that more plastic can be recycled, which then decreases the demand to produce additional brand new plastics.

This Is How Plastic Granulators Help Save The Environment By Reducing Waste

Plastic waste can take over hundreds of years to completely decompose, and this is only if it's not created into micro plastics. This long duration of time means that if we continue to produce new plastic at the same pace without recycling it, then soon there will be a large problem to solve for all. This is why plastic Granulators an integral for our Earth.

Plastic Granulator is a term fans of manufacturers around the globe are still using to describe this piece of machine which revitalizes plastic waste into a user-friendly and very-feasible new end product. This also minimizes the number of plastic getting dumped to landfills, hence reducing waste and is a lot more environment friendly. In addition, they are also energy efficient as Fosita designs its Plastic Granulators. That also means they consume less power and produce lesser pollution as compared to the older machines, which is great for our Environment.

Plastic Granulation for Making Better Plastic Products

You know how most plastic products appear to be are the same color of clear and smooth? This is due to them all having identical size and shaped plastic granules that they are made from. The hardiness of the plastic products makes it very important that they are manufactured consistently.

This means that if the plastic granules used to make a product all differed in size, it could fail as higher irregularity among granule sizes could result into lower strength of final part which may even split easily. This explains how very important a process granulation is in the manufacture of excellent plastic products.

The plastic Granulators that Fosita offers will be able to create perfectly shaped and high-quality pellets, which is perfect for all sorts of different types of products in the market. The hinges on the hopper doors to release rice are one particularly illustrative part of this fact, as they have never been replaced and continue to work perfectly — an example of how strong Fosita's products really are, which in turn makes customers feel safer about what it is that they're buying.

Plastic Granulator: A Complete Guide

Now that you realize the important of plastic Granulators in recycling, let's learn more about how these machines perform. Most budgeting for maintenance should be improved with better parts of the plastic Granulator, including hopper, rotor and screen.

At the beginning, the plastic waste is thrown in to a hopper of Granulators. Hopper: The hopper is the one that stores all plastic waste in machine. The waste is fed into the hopper, where it drops onto an otherwise rotating rotor. The rotor is a disc blade that rotates at high speed and shreds the piece of waste plastic.

Once the plastic waste has been chopped up, it falls through a screen. This is an essential item as it rids the small plastic pellets and leaves behind all grime. These clean granules are then gathered and melted down to develop new items we make use of every time.

Fosita plastic Granulators with high quality and advanced technology. This way, you can always trust them to be quality controlled and secured. That means the next time you see a plastic product, remember it was afforded to you by none other than your favorite brand of plastic Granulator — Fosita. These are the machines which plays an important role in recycling and make our environment greener.

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH