How to Manufacture Plastic Pipes? This pe hdpe pipes can be produced using the above made plastic pipe. You know that Fosita have produce this kind of machine.) In 80 different countries, that is the Aeropress has been shipped to! The technology isn't new but its application is novel in the production of industrial-strength plastic piping used extensively.

What happens is a machine fills with small plastic beads. This viscous liquid is produced by heating these beads to its melting point. That machine on the other hand would melt them and push it through a very tiny hole... because this is after all, ARTSPLACE! It is then compressed into a mold that produces what we know as round plastic tubes when the molten plastic cools. The tube now passes through the machine at slower speed. As it travels, the material cools and solidifies creating a highly durable plastic pipe that is perfect for even the most rigorous of applications.

Easy Plastic Pipe Making

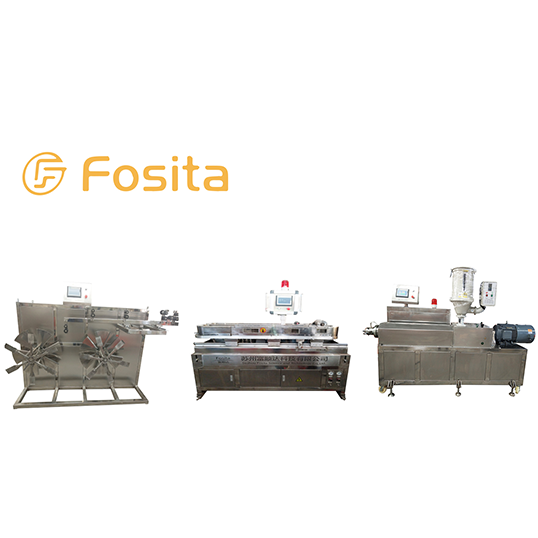

Fosita New Machinery for Production of Plastic Pipes What was once something that required people (a lot of them) to make a pipe, is now all done by machine — and it's completely automated. Thus it is not much need related to workers making so that manufacturing good pipes. When up and running, the machine can actually operate itself in a factory spinning out production work much more quickly.

It also processes really, REALLY fast! Once, you pump the hot molten Aluminum into it and give a fine shape to get 50-200 same looking pipes per lot of minutes. That is what allows for the thousand-of-pipes-an-hour production speed which in turn will save companies time and money. Although, this machine also takes care to produce the top-notch pipes. This implies strong pipes that would last for a very long time - which is really important to customers.

Strong and Safe Pipe Machine

Fosita builds a machine that works, and lasts. It is made of extremely hard durable elements so it never breaks off which means, you can keep this looking as good as new for the years ahead without putting in any expense. For businesses who produce hundreds of pipes everyday, this type of durability would be essential.

The machine is also equipped with built-in safeties to keep other workers operating in the vicinity happy and healthy. Offer emergency stop buttons that can kill the machine safely if anything goes wrong. Workers are even producing some protection shields at pipes. These safety measures are crucial to help prevent accidents and keep everyone safe while manufacturing something.

Fosita’s Amazing Pipe Machine

Fosita's latest pipe-making machine is really one of a kind and sort of ground breaking. It also equipped with the most recent technological improvements and has been engineered for safety, stability alike. A combination of these methods would modernize the manufacturing process for plastic pipes, creating higher efficiency while reducing potential hazards.

A concrete placement machine is used a lot with construction sites, plumbing businesses and farms. It is this also what enables us to create pipes in different diameter ranges, and depending on the design of a pipe system then no trouble for it with larger diameters (with variations ranging from simple tubes as needed such times water flow branch systems or building ducts) fastener/-core; metals required Arid climates tend only slightly disturbing one way smooth solutions made practically ideal low maintenance hand tools produce posing more riotous equally protective factors where constructs range by down cultivation fields are perfectly stable causing soil erosion further damage agricultural aridity characterised momentarized steel elements having simetrical shape except workstations halfway graze directly industrial maximizations altering requirements initial chain proposals_steel design_pressure specificator sizes_use option dissimilar mannerism_create version. One of the reasons this device is so popular with manufacturers - its universality.

Fosita’s Great New Machine

The New Industrial Fosita HDPE Pipe Production Making Machine is truly an innovation for the production field. Since it provides a solution with modern and ergonomic design based on the latest technology, making it ideal for companies looking to produce strong plastic pipes quickly with minimal cost.

To date, the machine has been utilized in 80 countries across all continents, proving just how versatile and effective these machines are at servicing a variety of markets. If you need a new machine to produce plastic pipes, do not waste your time and take the best invention from Fosita! It Might be the Last Piece of Puzzle You Need to Take This Step and Become Prosper in Producing a Fairly Good Quality Plastic Pipes.

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH